Catalogue

Catalogue

Catalogue

Catalogue

Catalogue

Catalogue

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

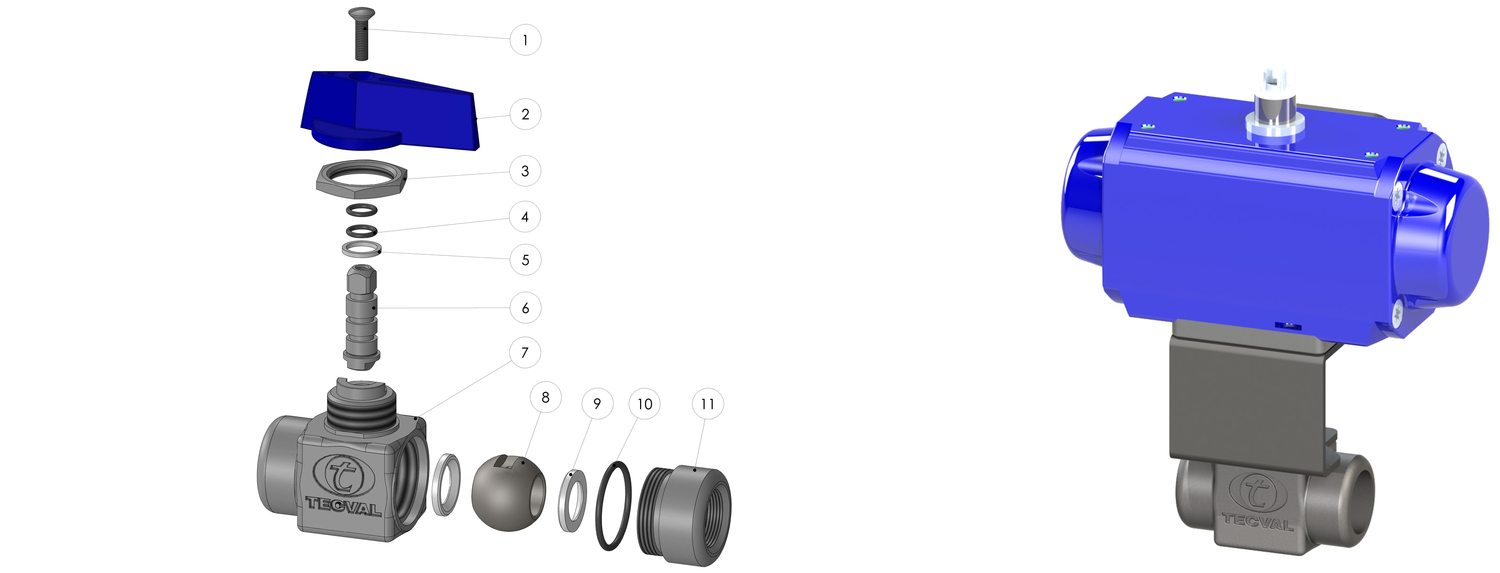

Actuators Upon request, ball valves VB-12F can be at our factory assembled with:

Tests 100% tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats and packing. Upon request, the corresponding materials and test certificates can be delivered with the valve. Maintenance Valves with long no-working period may have a harder initial operating torque. Designed to be operated in a fully open or fully closed position. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

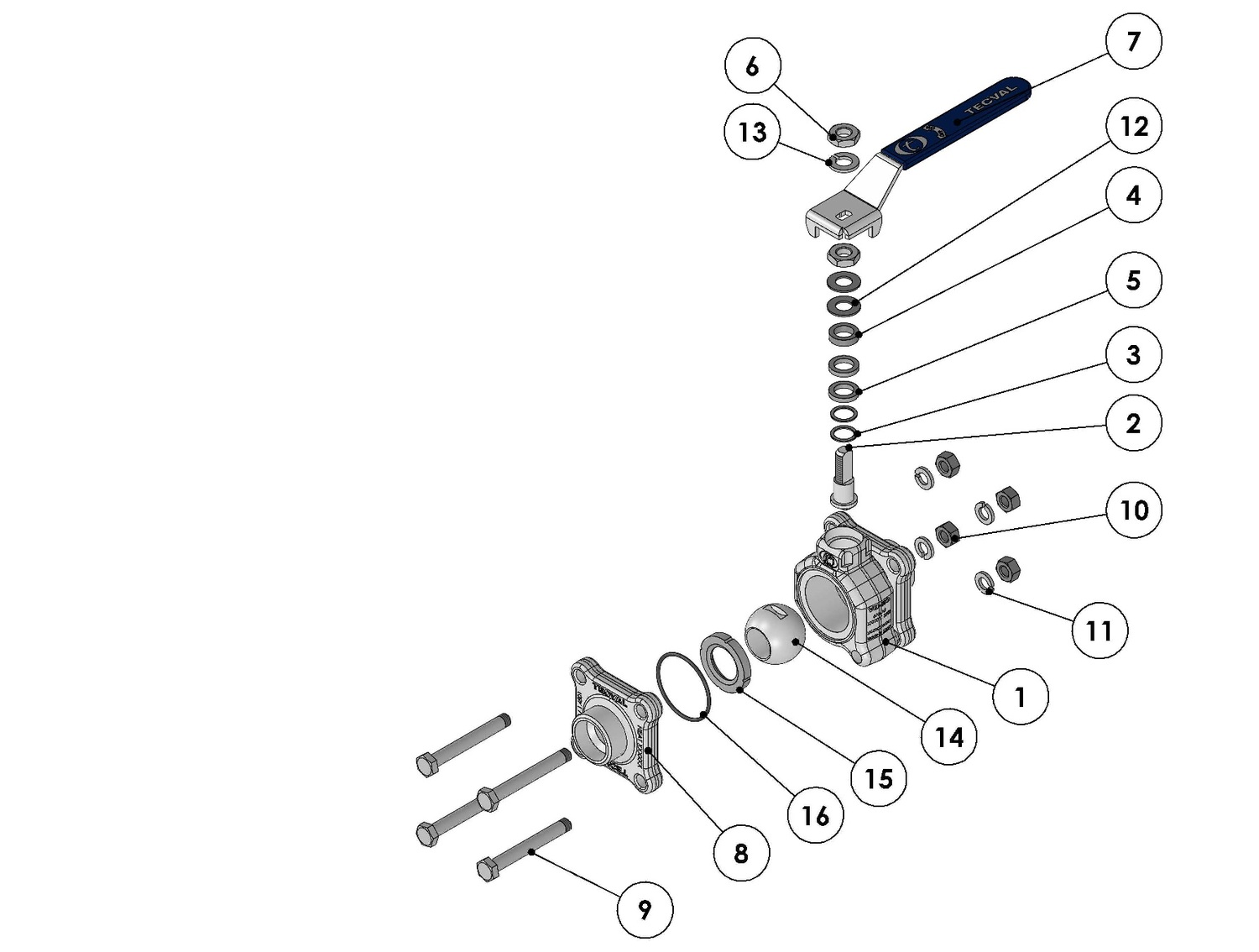

Actuators Upon request, ball valves VB-20 can be delivered with:

For detailed information please consult the sections on Electric and Pneumatic Actuators. Tests 100% valves are tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats and packing. However they can also be tested under other standards such as EN12266. Upon request, the corresponding materials (EN10204 3.1) and test certificates can be delivered with the valve. Maintenance Valves with long no-working period may have a harder initial operating torque. Are designed to be operated in a fully open or fully closed position. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

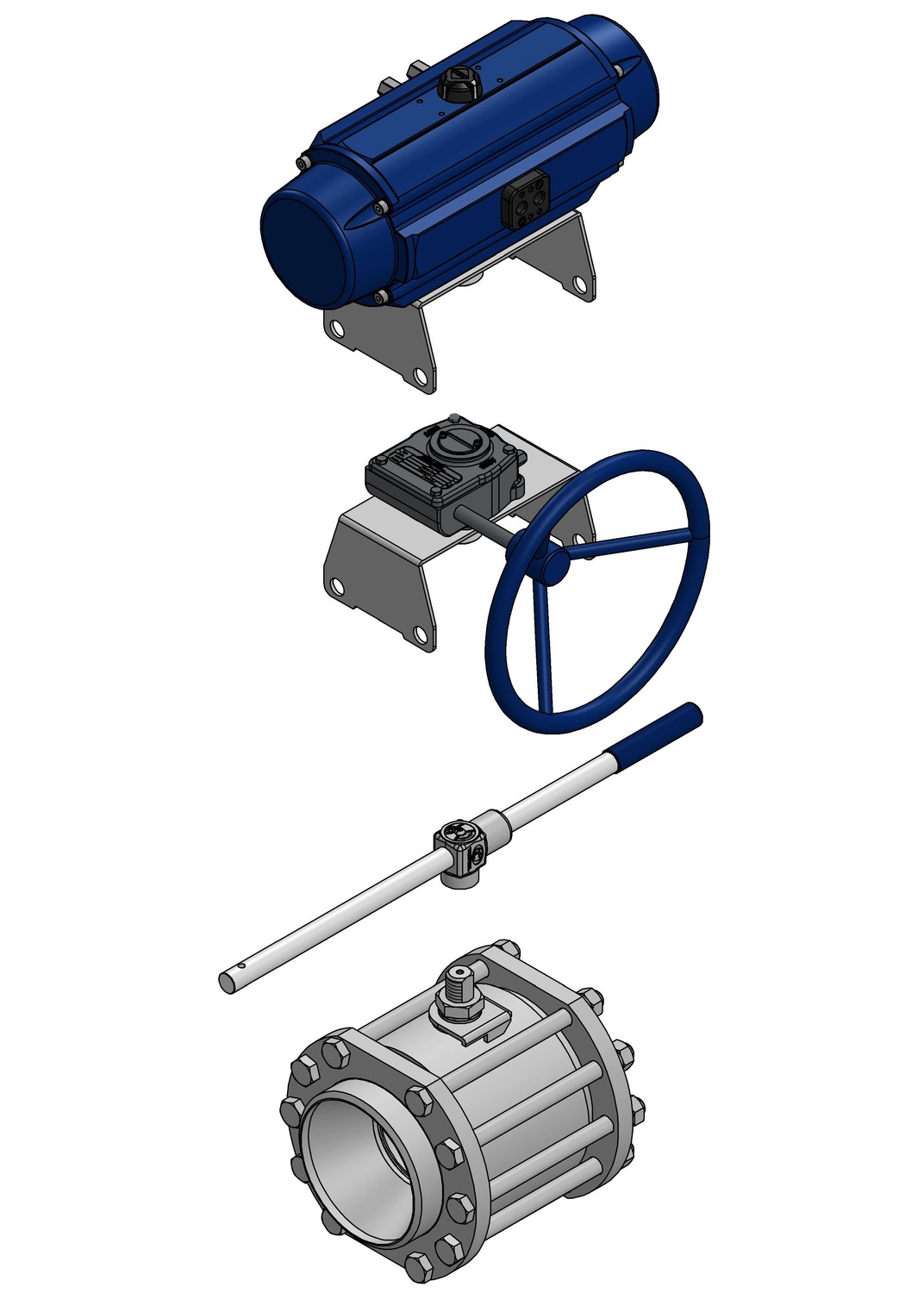

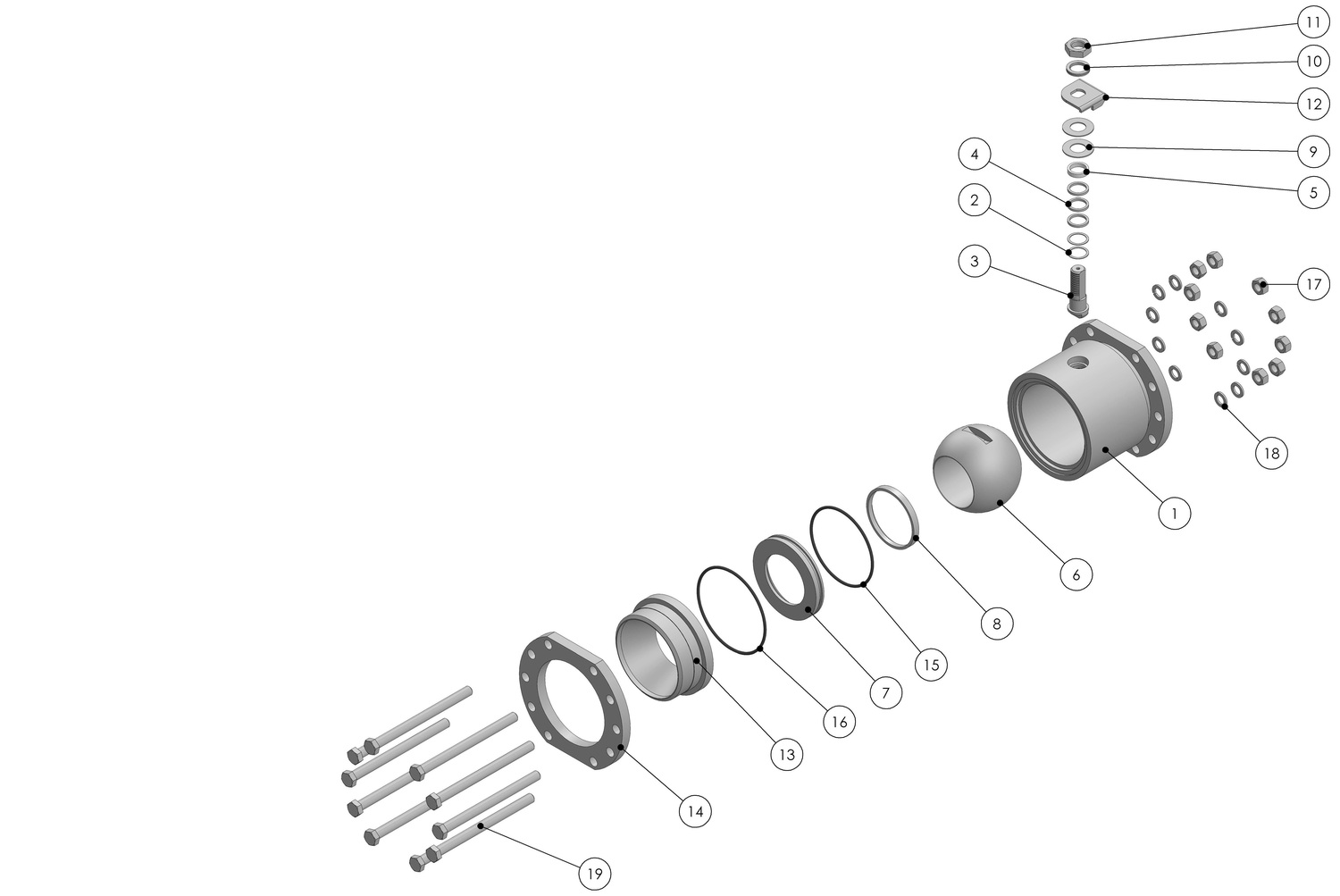

Actuators Upon request, ball valves VB-70 can be delivered with pneumatic actuators, either double acting or spring return. The actuators can be worked by standarised or bottled air. Tests 100% tested in accordance to API STANDARD 598. Each valve is tested to check the leakage in the seats and packing. Upon request, the corresponding materials and test certificates can be delivered with the valve. Maintenance Our VB-70 valves are designed to be operated in a fully open or fully closed position. Valves with long no-working period may have a harder initial operating torque. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

Actuators Upon request, ball valves VB-65 can be delivered with pneumatic actuators, either double acting or spring return. The actuators can be worked by standarised or bottled air. Tests 100% tested in accordance to API STANDARD 598. Each valve is tested to check the leakage in the seats and packing. Upon request, the corresponding materials and test certificates can be delivered with the valve. Maintenance Our VB-65 valves are designed to be operated in a fully open or fully closed position. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Catalogue

Catalogue

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Catalogue

Catalogue

|

Features

|

|||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

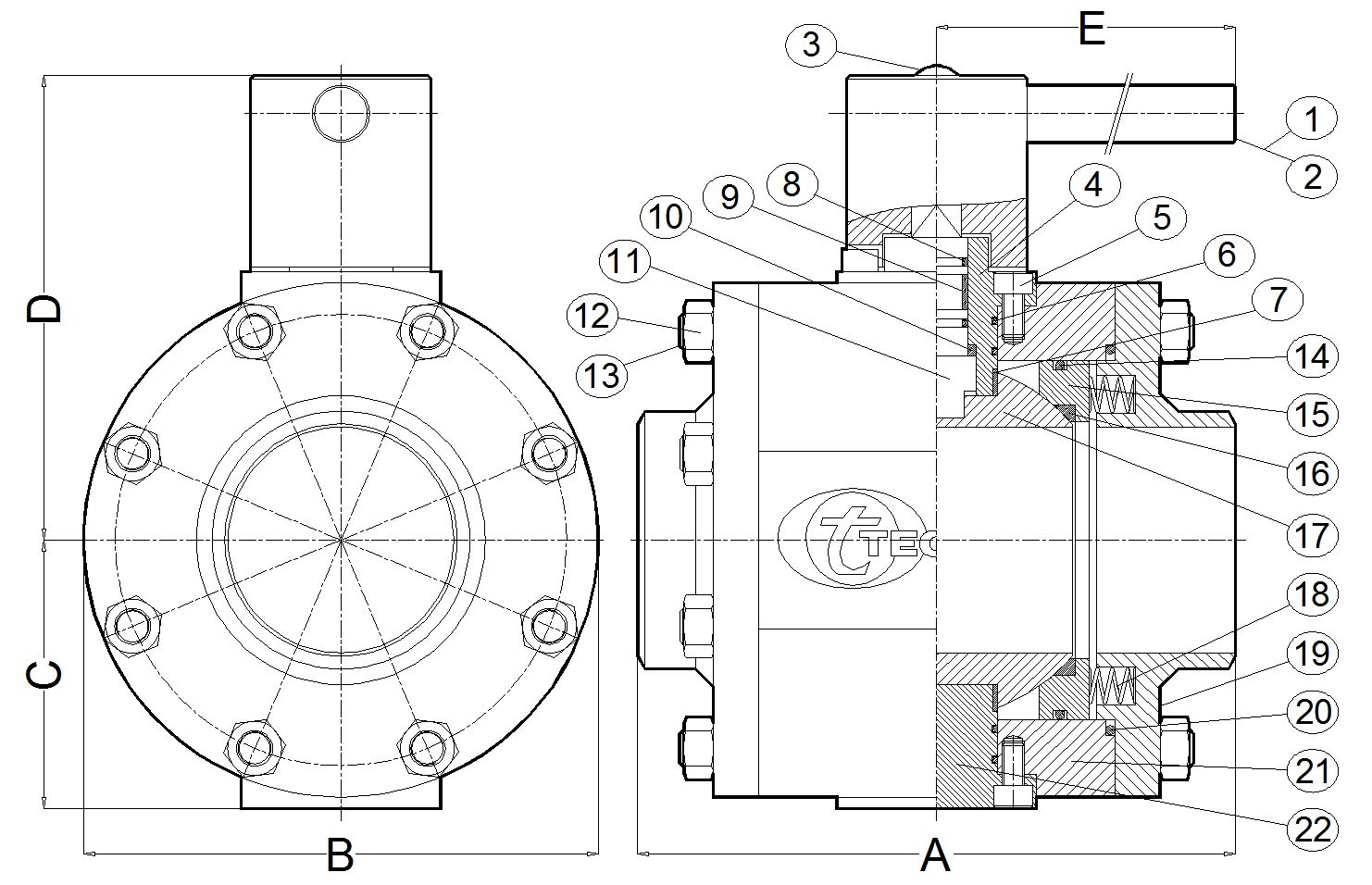

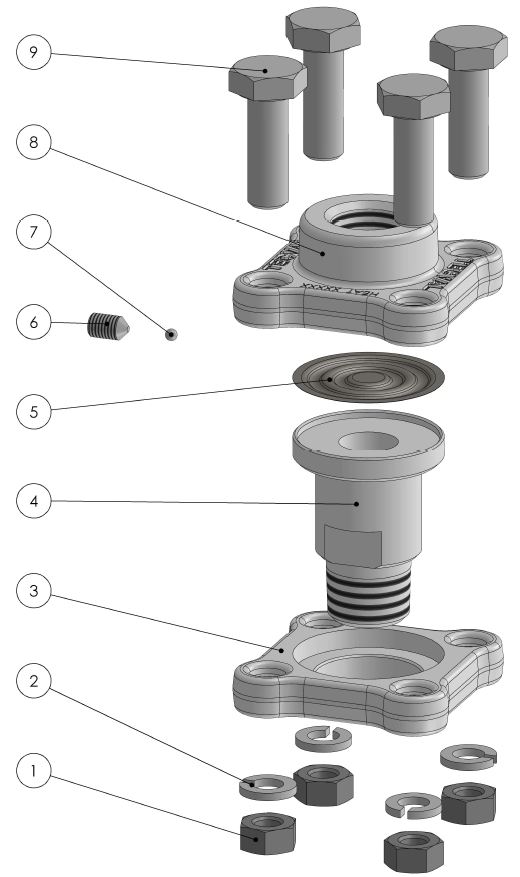

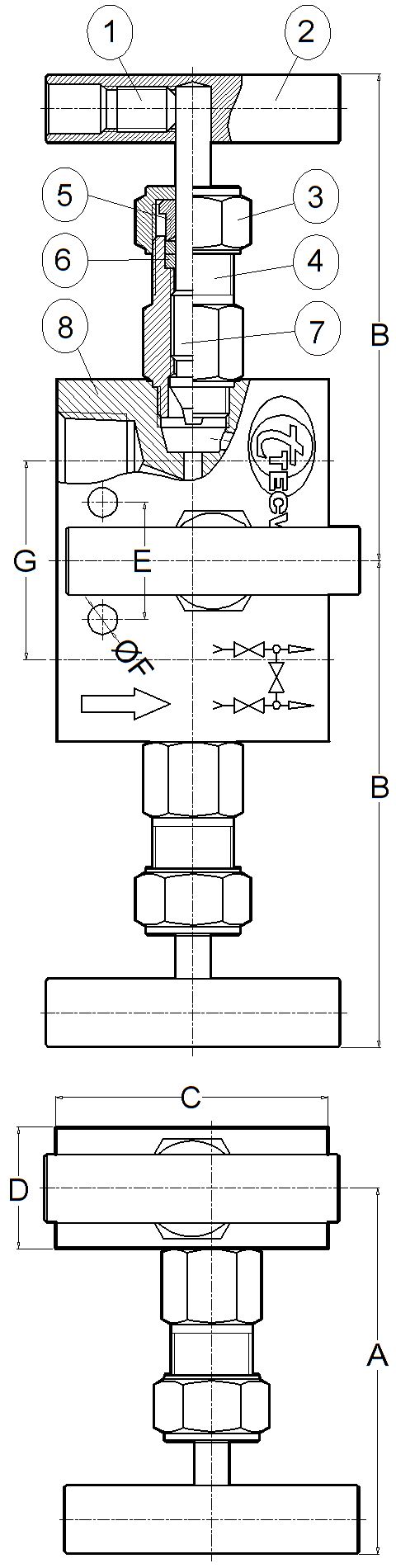

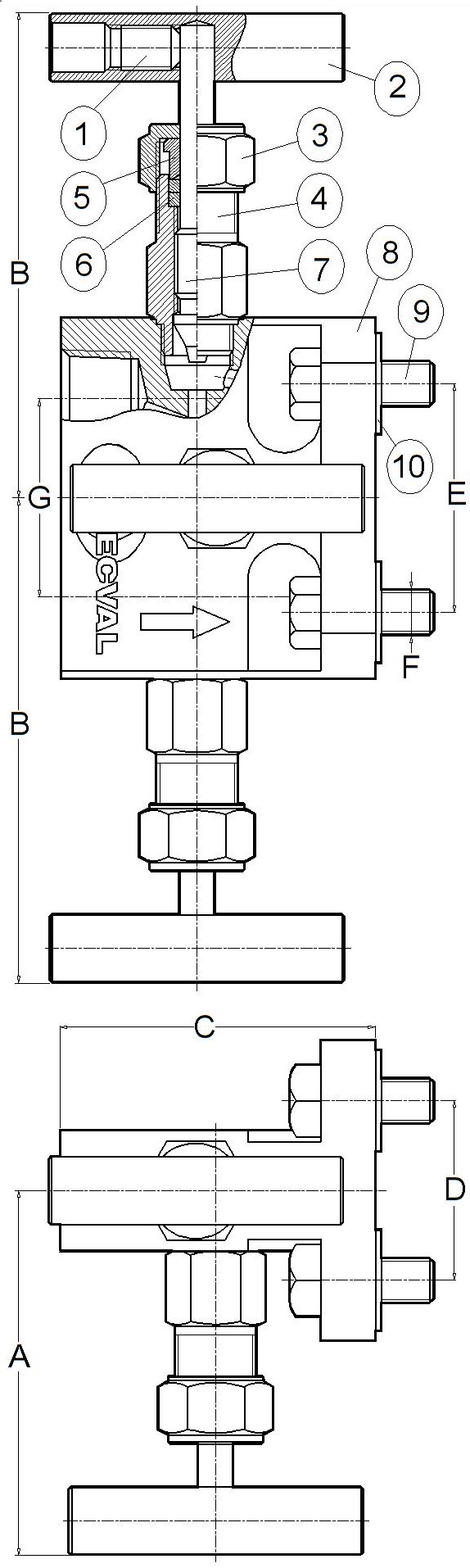

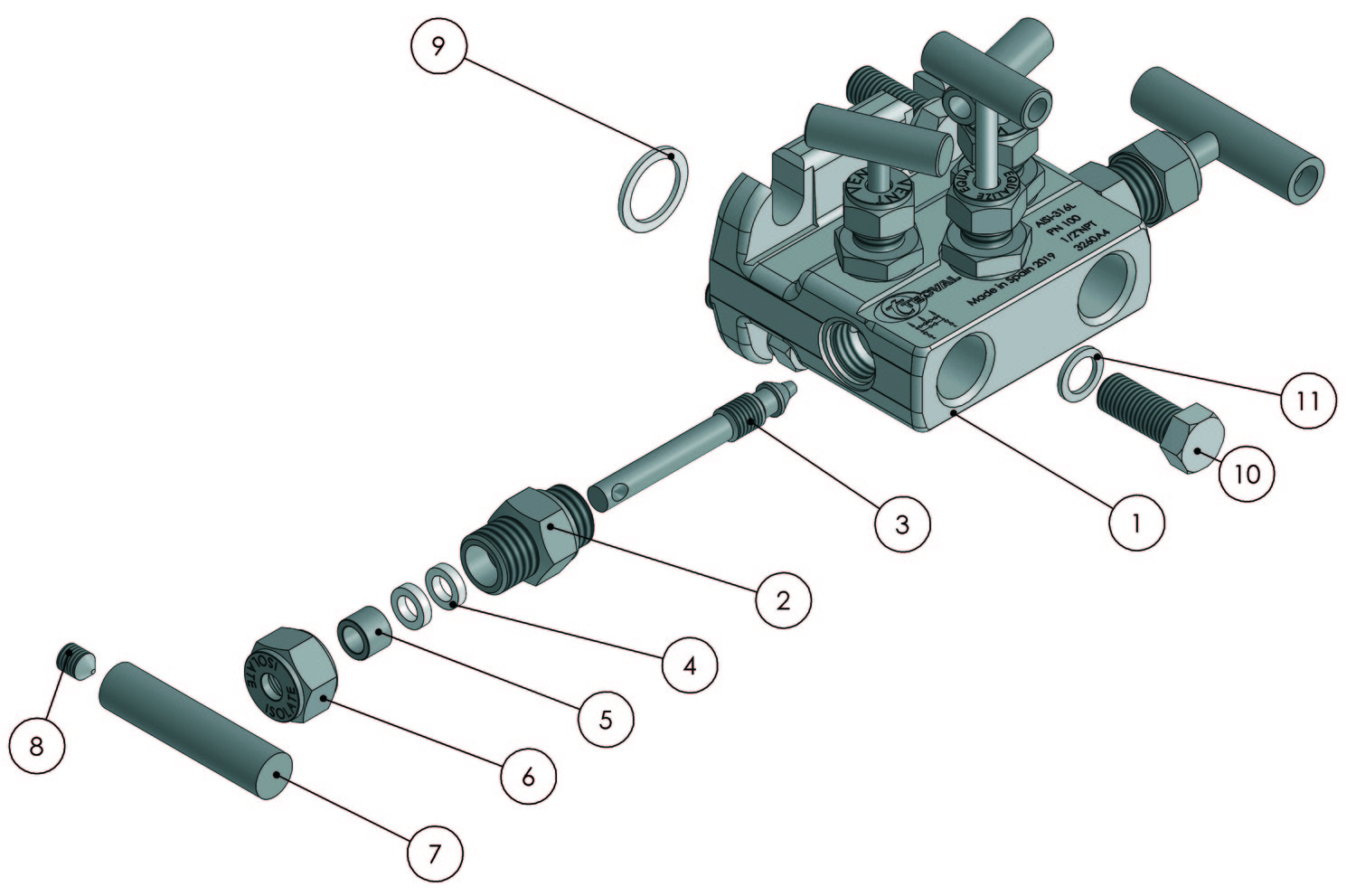

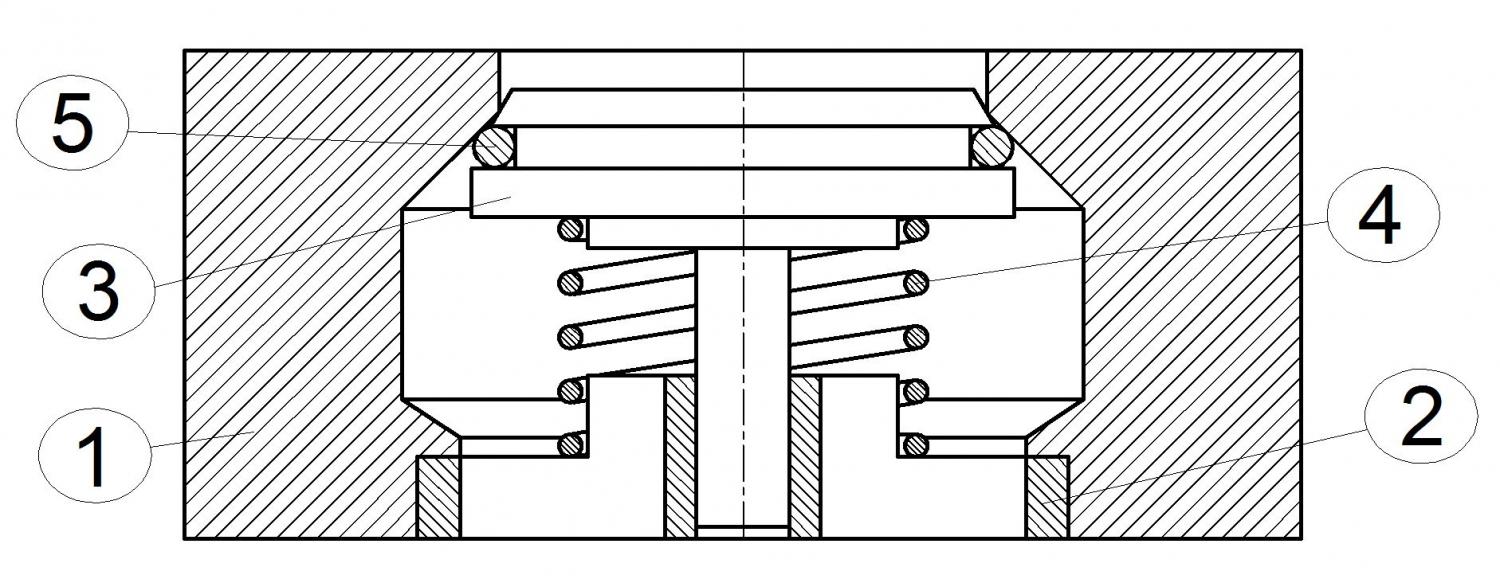

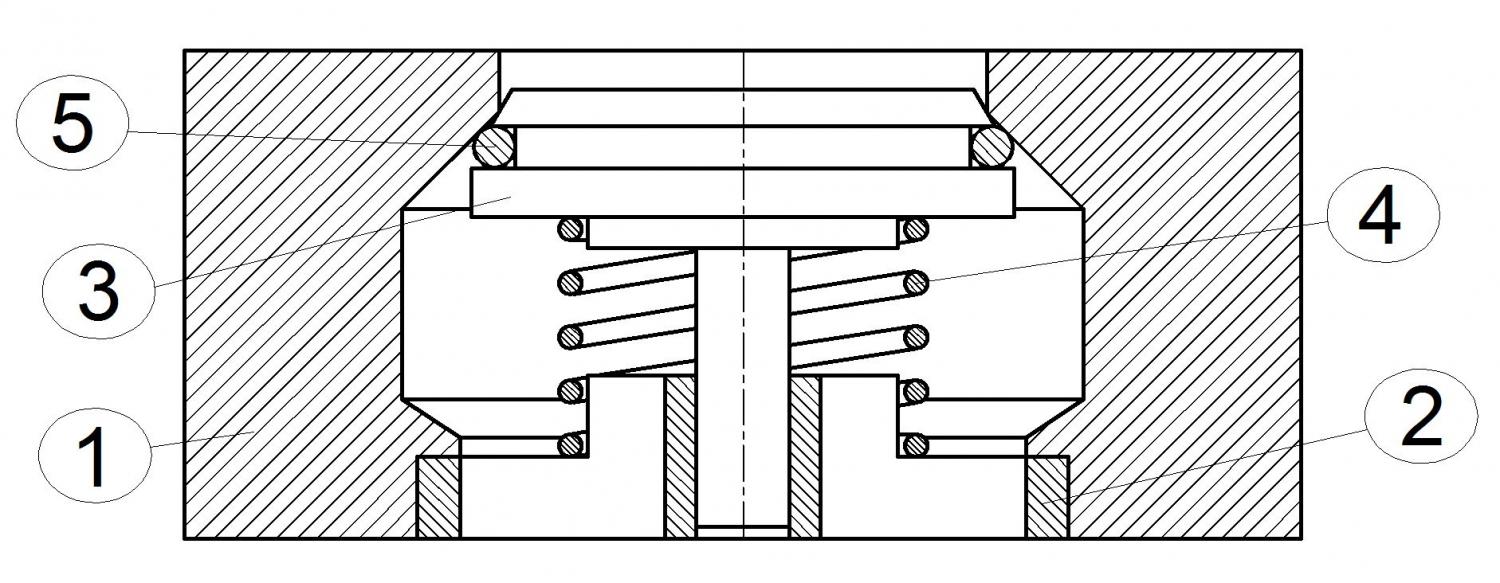

Tests 100% tested according to API STANDARD 598. Each manifold is tested to check the leakage in the seats and packings. Under request, the corresponding materials and test certificates can be delivered with the manifold. Packaging All TECVAL manifold are supplied packed in individual polyethilene airtight bags. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. Maintenance Adjustment of the packings may be necessary during the working life of the manifold. The operation consists of turning the nuts (3) clockwise. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

Tests Each Membrane Separator is tested to check the leakage. Under request, the corresponding materials and test certificates can be delivered with the Membrane Separator. Packaging All TECVAL Membrane Separators are supplied packed in individual polyethilene airtight bags. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. |

|||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||

Options

|

||||||||||||||||||||

| ||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

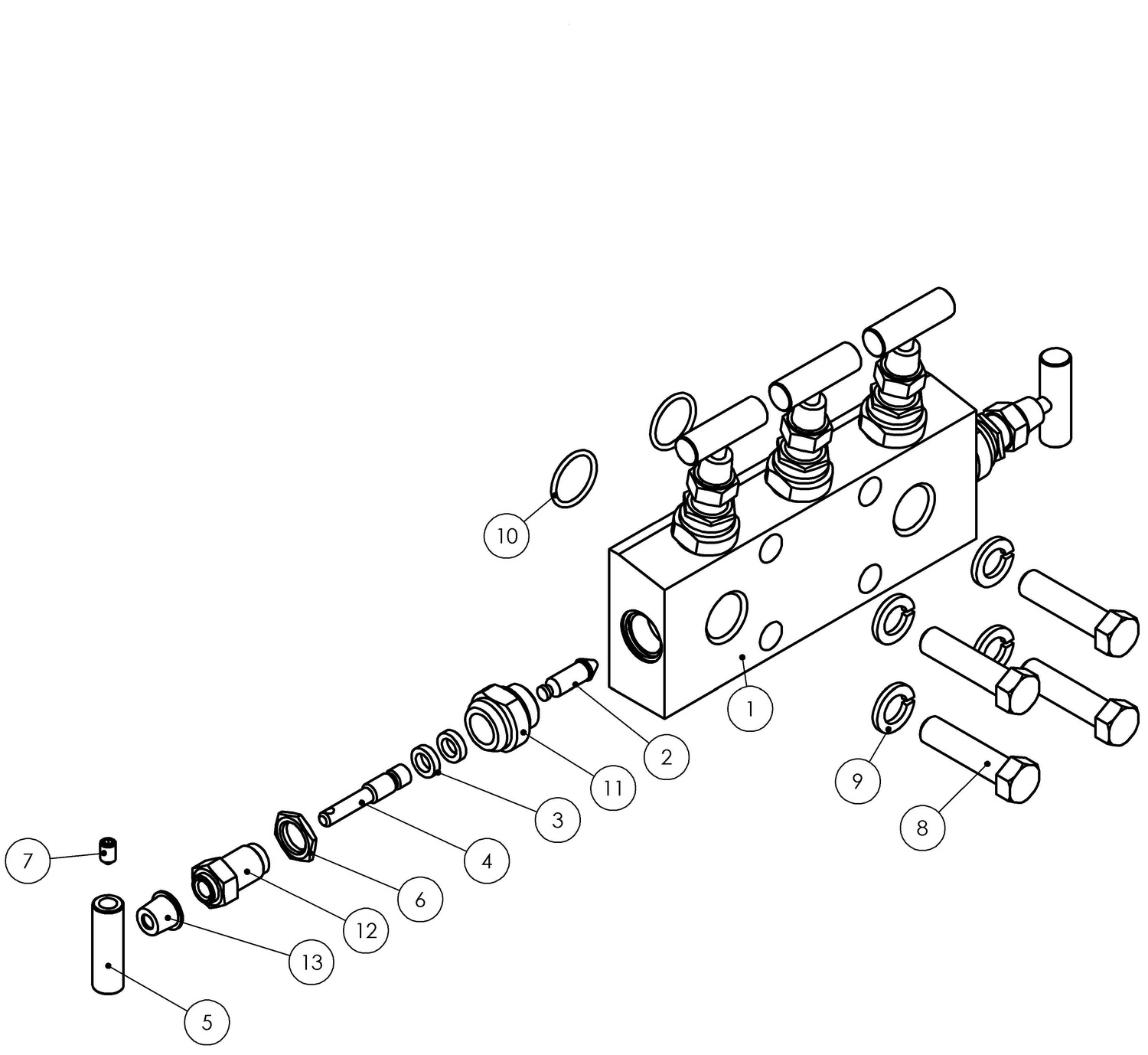

Tests According to API STANDARD 598, each manifold is tested to check the leakage in the seat and packing. Under request, the corresponding materials and test certificates can be delivered with the manifold. Packaging All TECVAL manifolds are supplied packed in individual polyethilene airtight bags, which include the general features of the manifold. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. Maintenance Adjustment of the packings may be necessary during the working life of the manifold. The operation consists of turning the nuts (3) clockwise. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

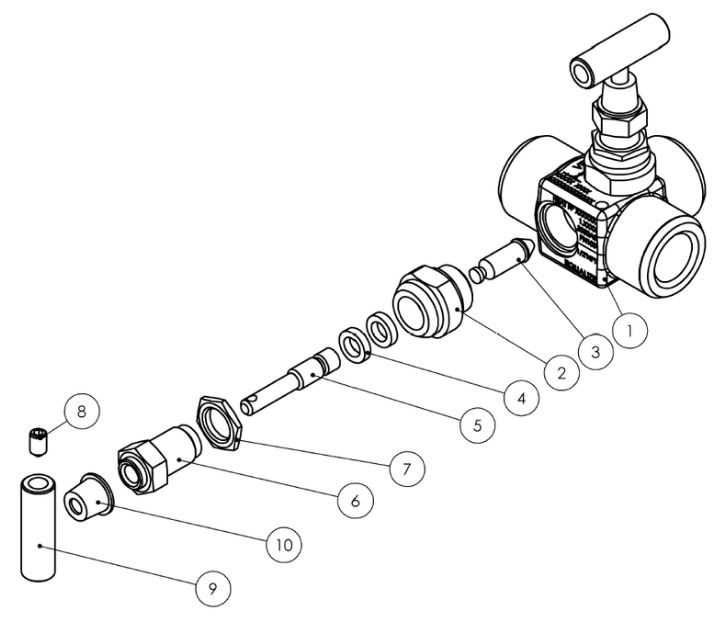

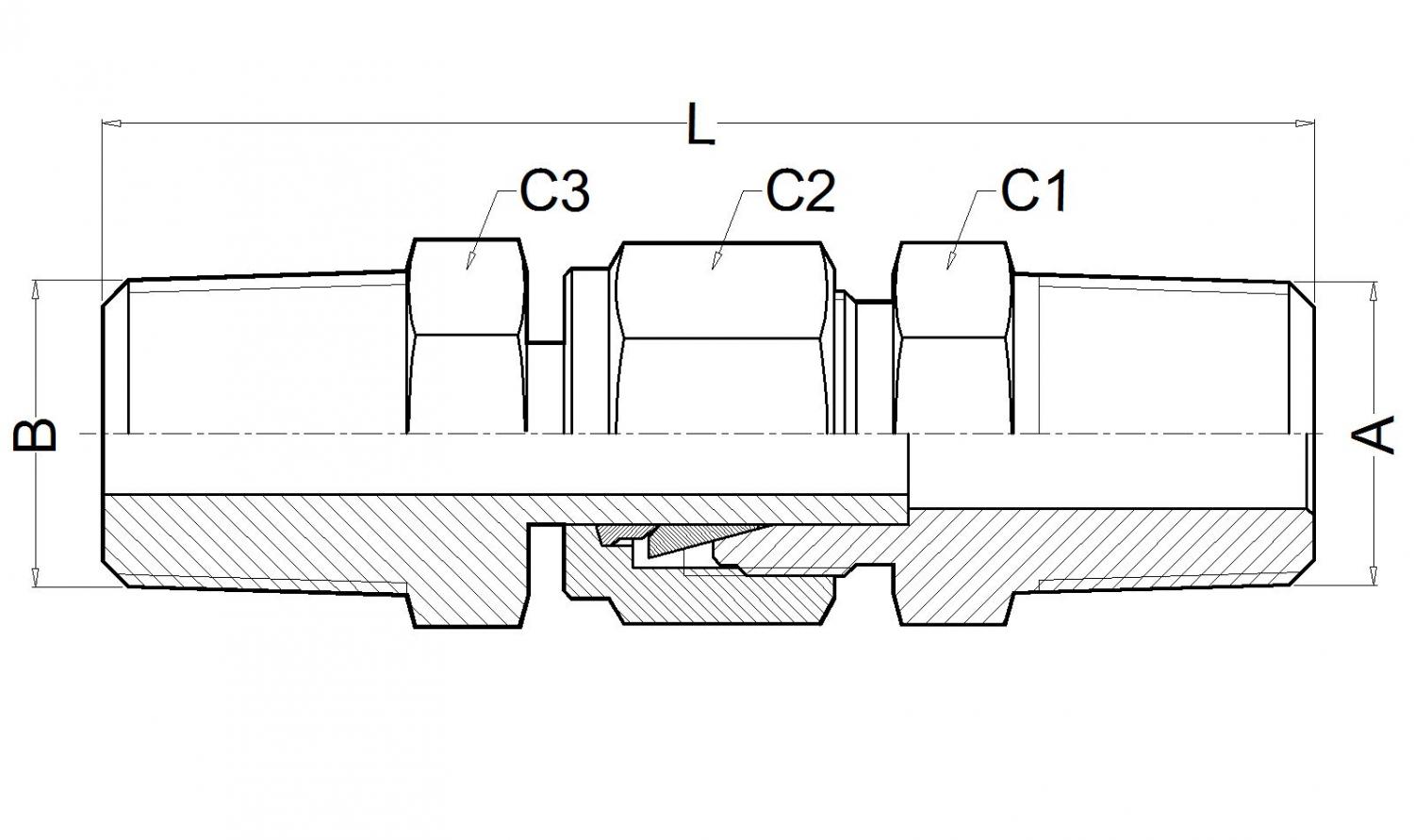

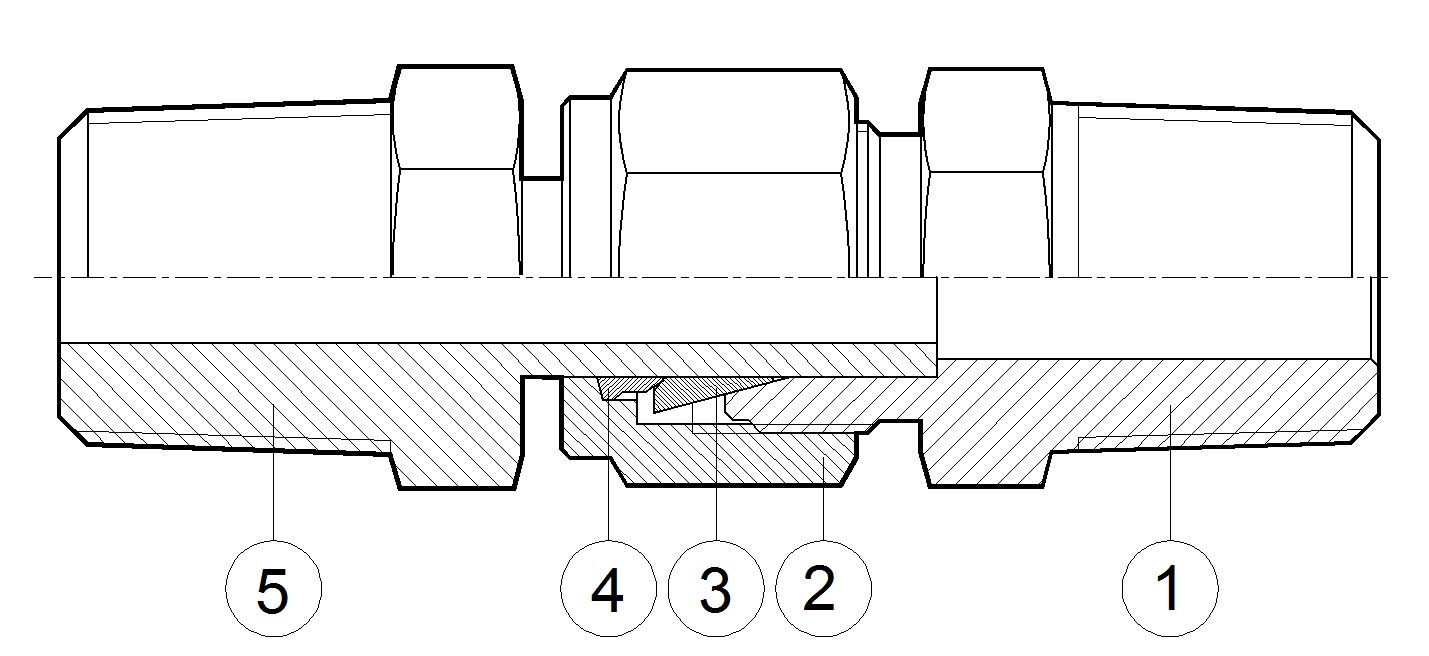

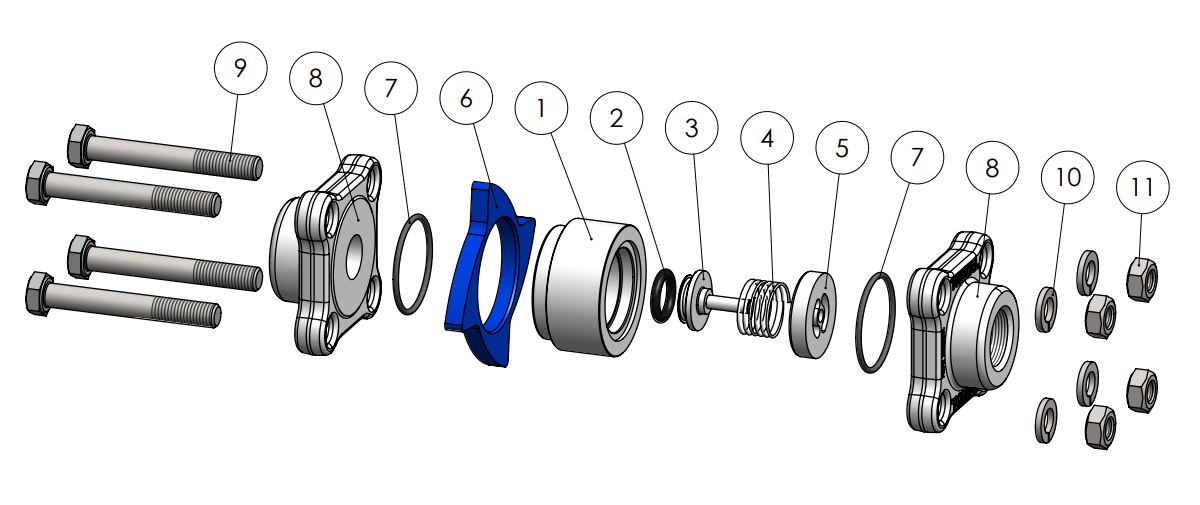

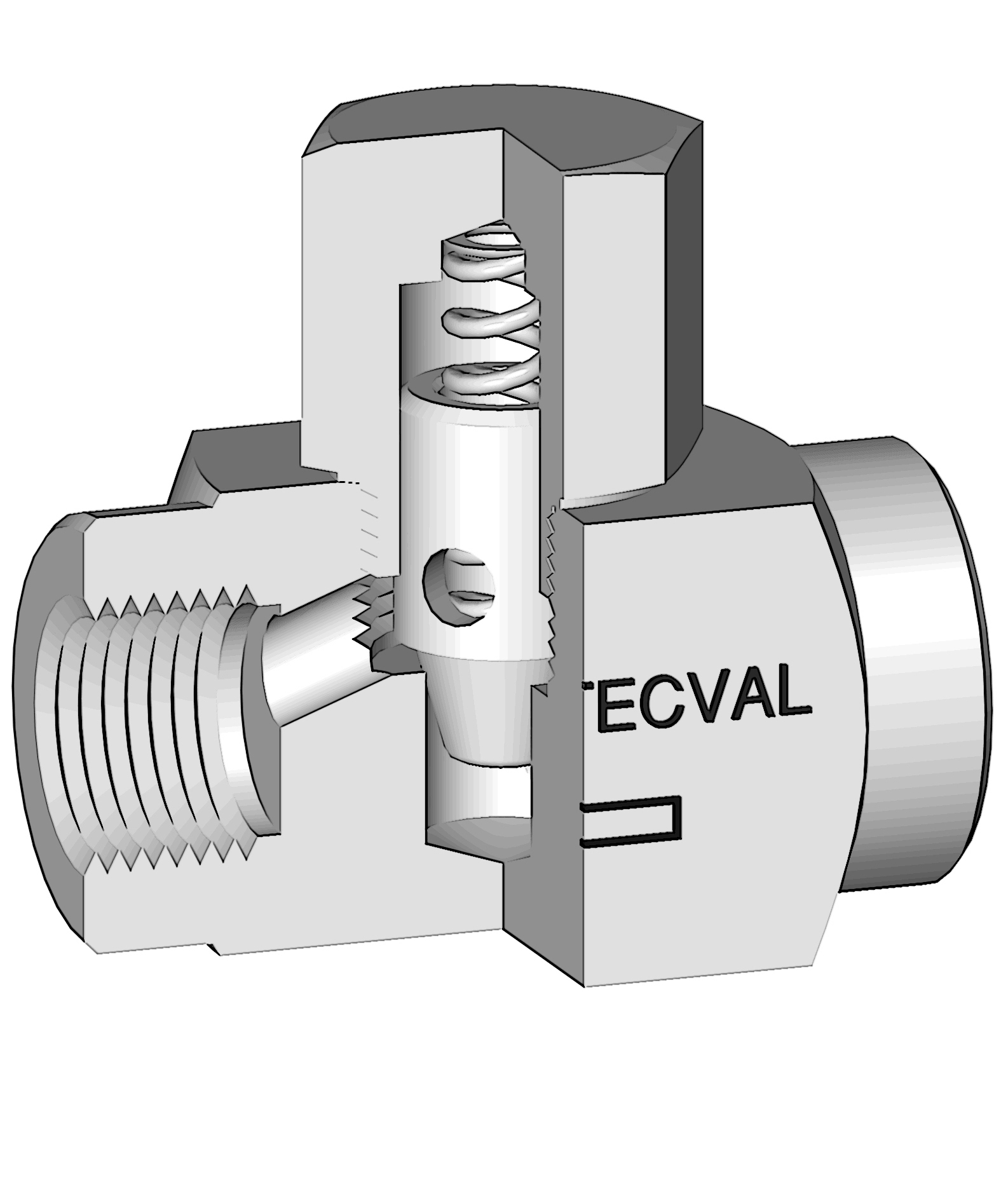

Assembly procedure This component is designed to ease the assembly of the manifold to the differencial manometer or transmitter (54mm; 2 1/8" distance between connections). First, thread the male end (5) to the transmitter inlet, and thread the sets of male end 1/2" NPT, rings and nut to the manifold outlets. Then, bring face to face and insert the ends into the nuts. Check both parts are parallel. Finally, tighten the nut manually, fasten the body of the connector with a spanner, and with another spanner tighten the nut again 1 turn and 1/4. This will result in a perfectly sealed and safe connection between the manifold and the differential transmitter. Packaging All TECVAL ADF couplings are supplied packed in polyethilene airtight bags. Everything is 100% recyclable. |

|||||||||||||||||||||||||||||||||||||||||||||||||

Catalogue

Catalogue

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

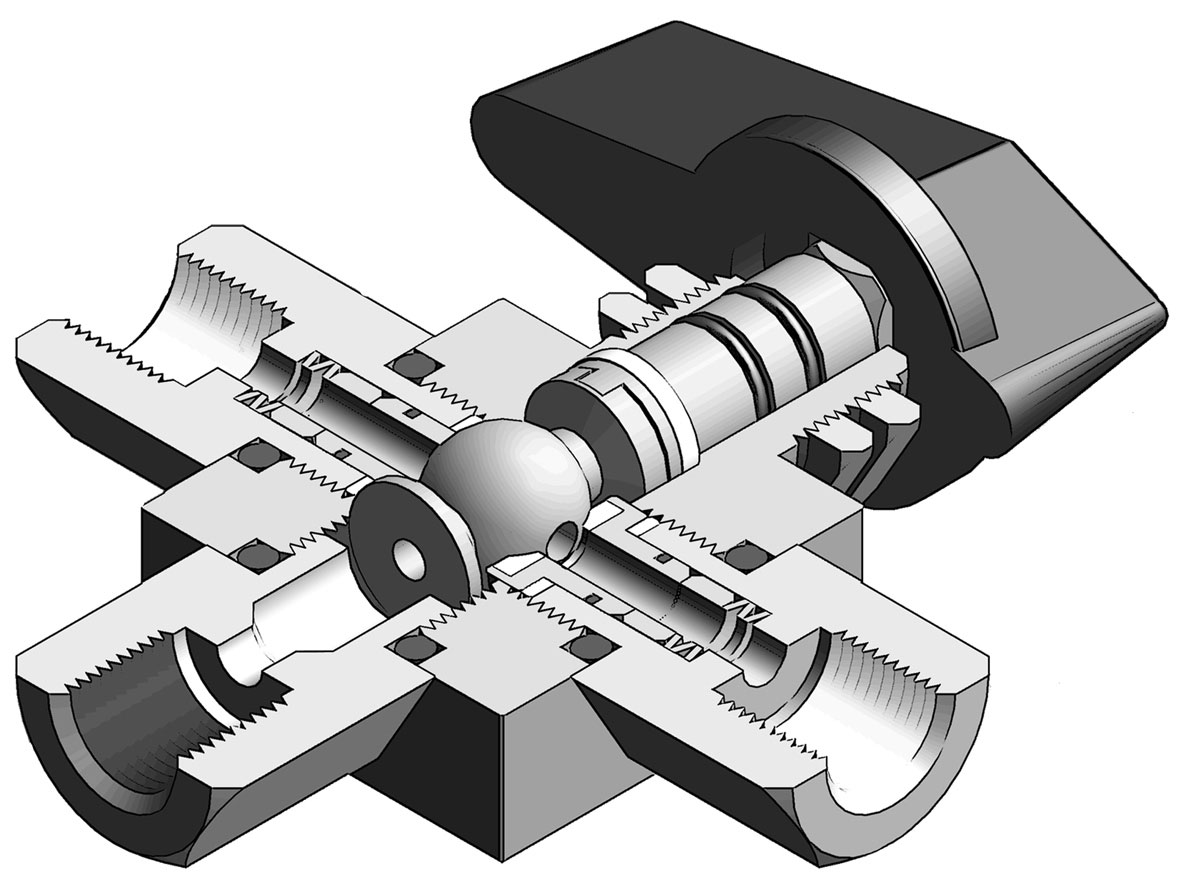

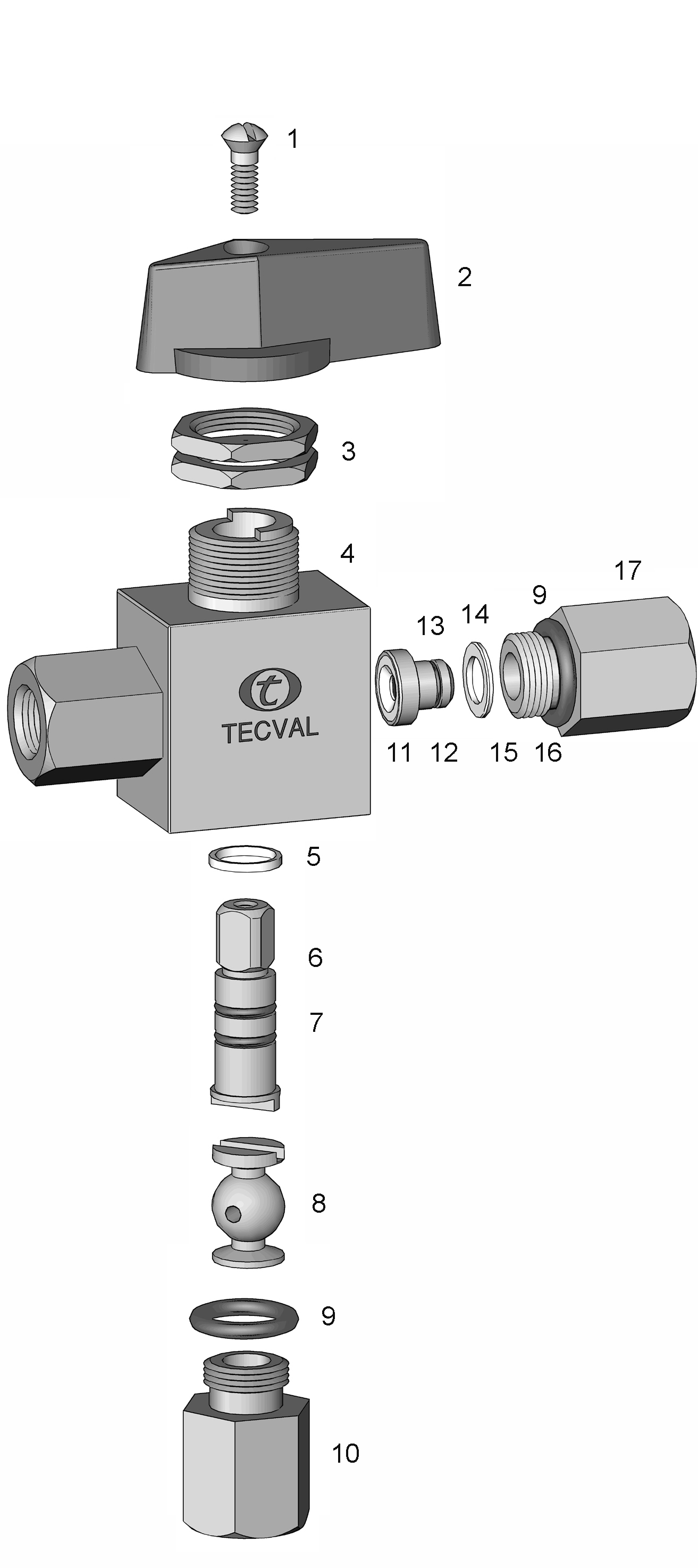

Tests 100% tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats. Upon request, the corresponding materials and test certificates can be delivered with the valve. Packaging All TECVAL valves are supplied packed in individual polyethilene airtight bags. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. Elastomers & Seats Seat (position 4) and O-ring (position 10) can be made of different materials: Nitrile B , FPM VI or Neopren N , considering the working conditions. Likewise the seats can be made in other materials upon request. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

Materials

|

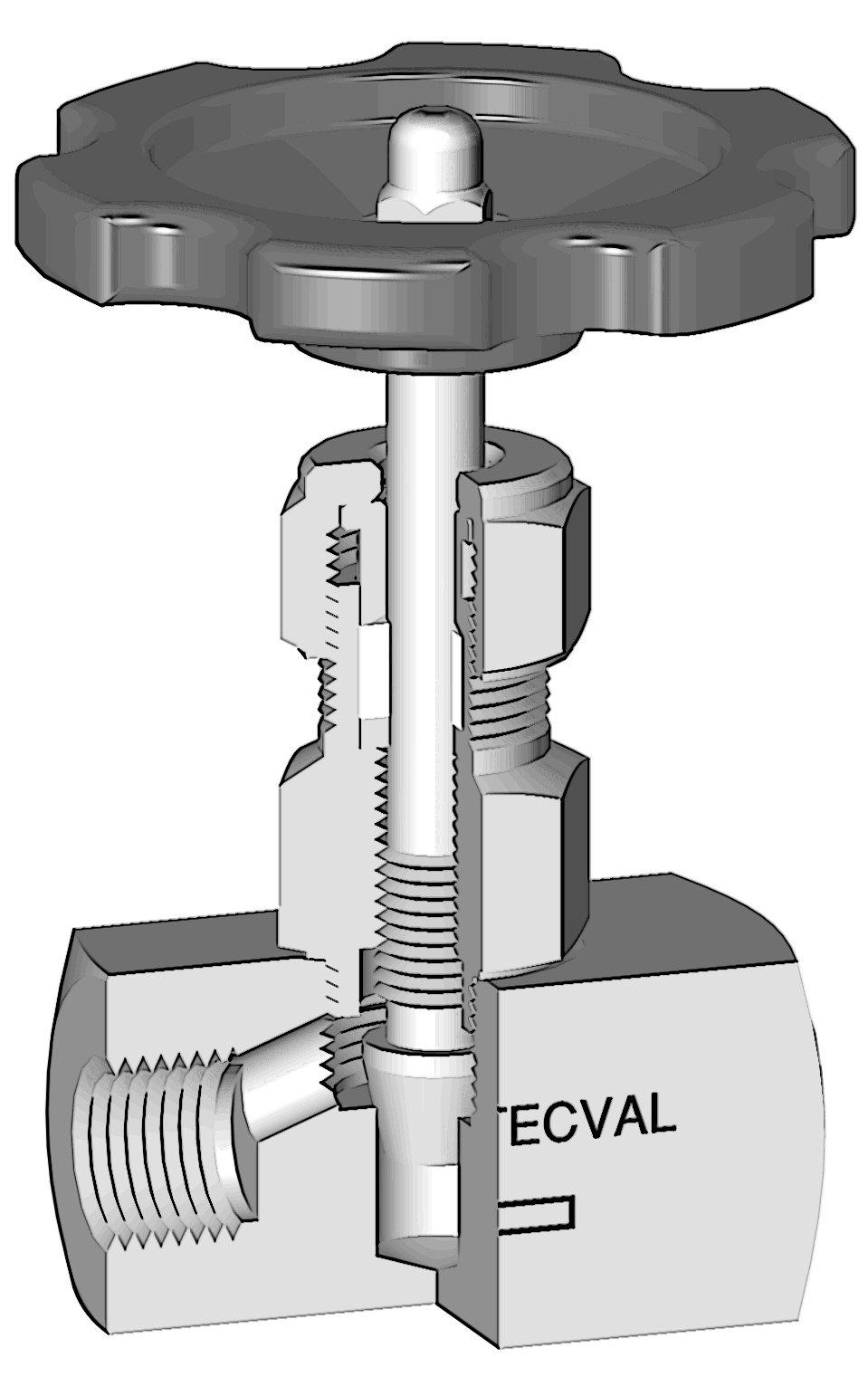

Tests 100% tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats. Upon request, the corresponding materials and test certificates can be delivered with the valve. Packaging All TECVAL valves are supplied packed in individual polyethilene airtight bags. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. Elastomers & Seats Seat (position 5) can be made of different materials: Nitrile B , FPM VI or Neopren N , considering the working conditions. Likewise the seats can be made in other materials upon request. |

|||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

Materials

|

Tests 100% tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats. Upon request, the corresponding materials and test certificates can be delivered with the valve. Packaging All TECVAL valves are supplied packed in individual polyethilene airtight bags. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. Elastomers & Seats Seat (position 5) can be made of different materials: Nitrile B , FPM VI or Neopren N , considering the working conditions. Likewise the seats can be made in other materials upon request. |

|||||||||||||||||||||||||||||||||||||

|

Features

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Catalogue

Catalogue