Catalogue

Catalogue

Check Valves

Catalogue

Catalogue

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials

|

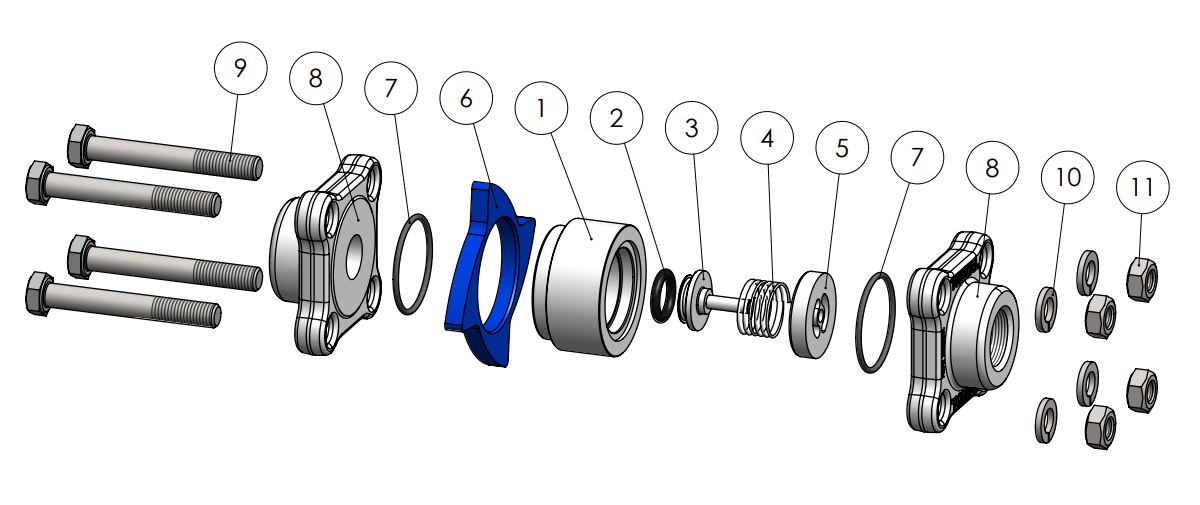

Tests 100% tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats. Upon request, the corresponding materials and test certificates can be delivered with the valve. Packaging All TECVAL valves are supplied packed in individual polyethilene airtight bags. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. Elastomers & Seats Seat (position 4) and O-ring (position 10) can be made of different materials: Nitrile B , FPM VI or Neopren N , considering the working conditions. Likewise the seats can be made in other materials upon request. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

Materials

|

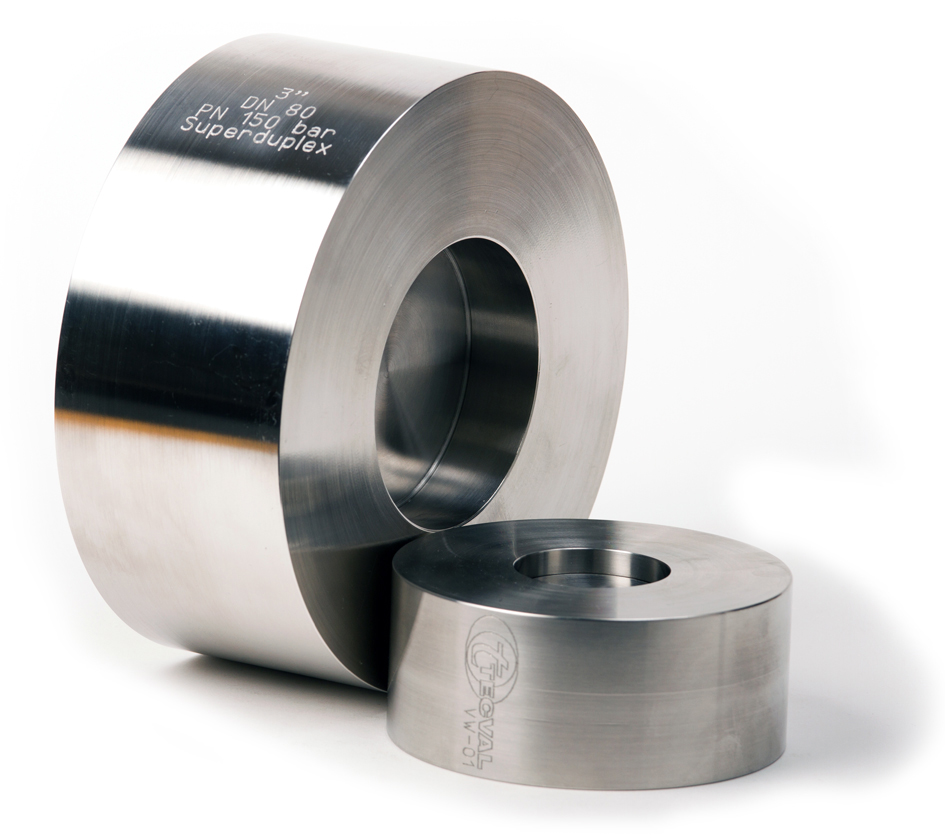

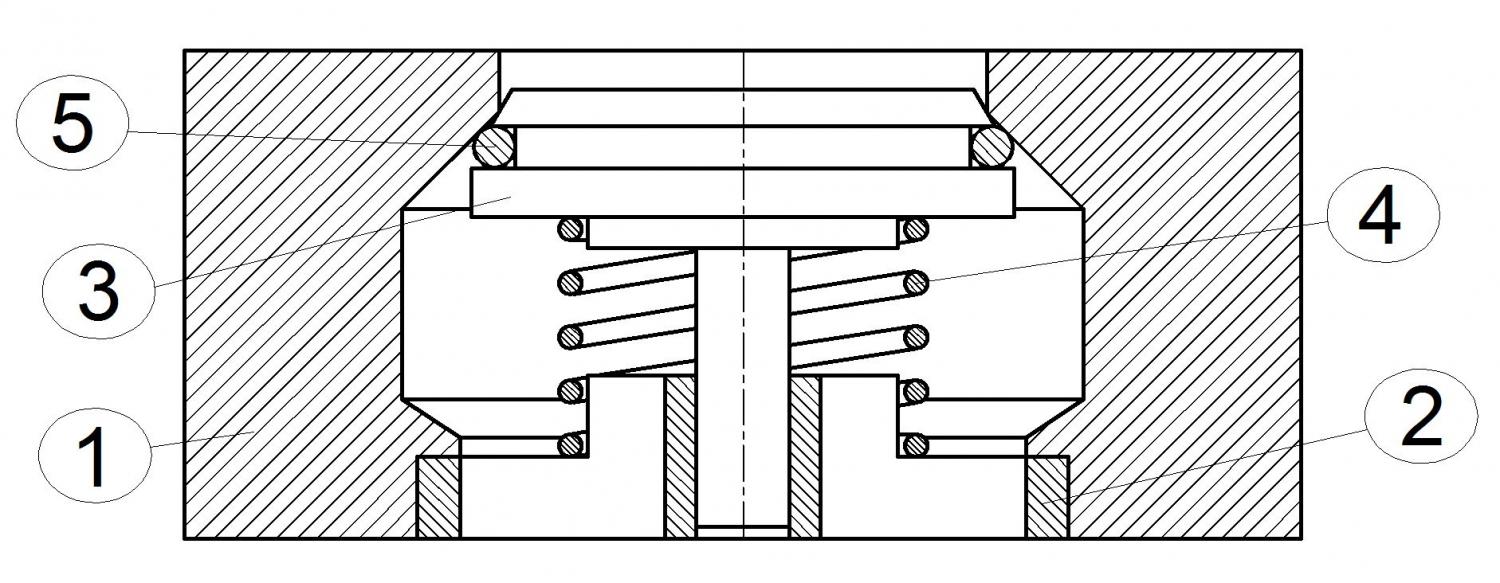

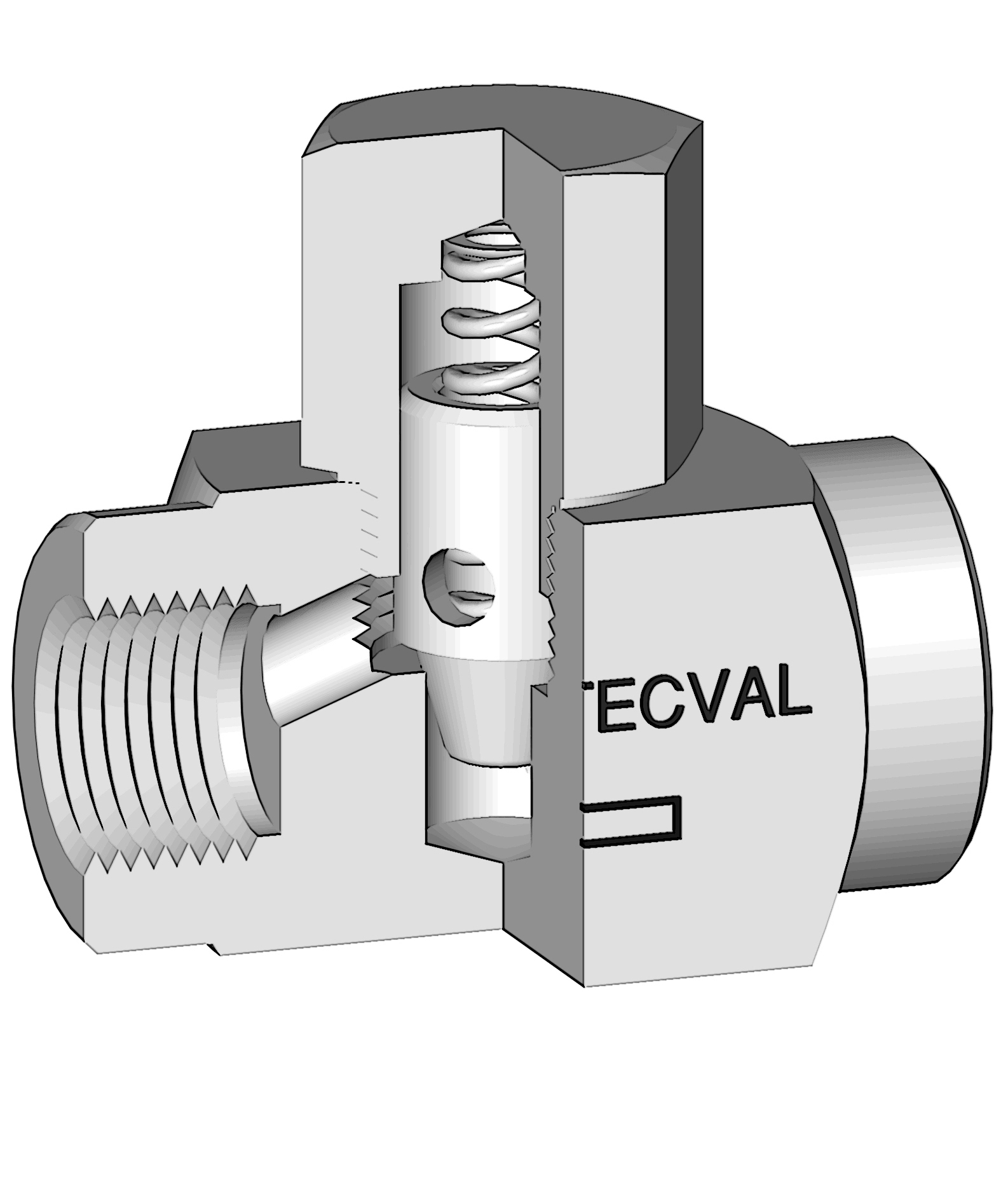

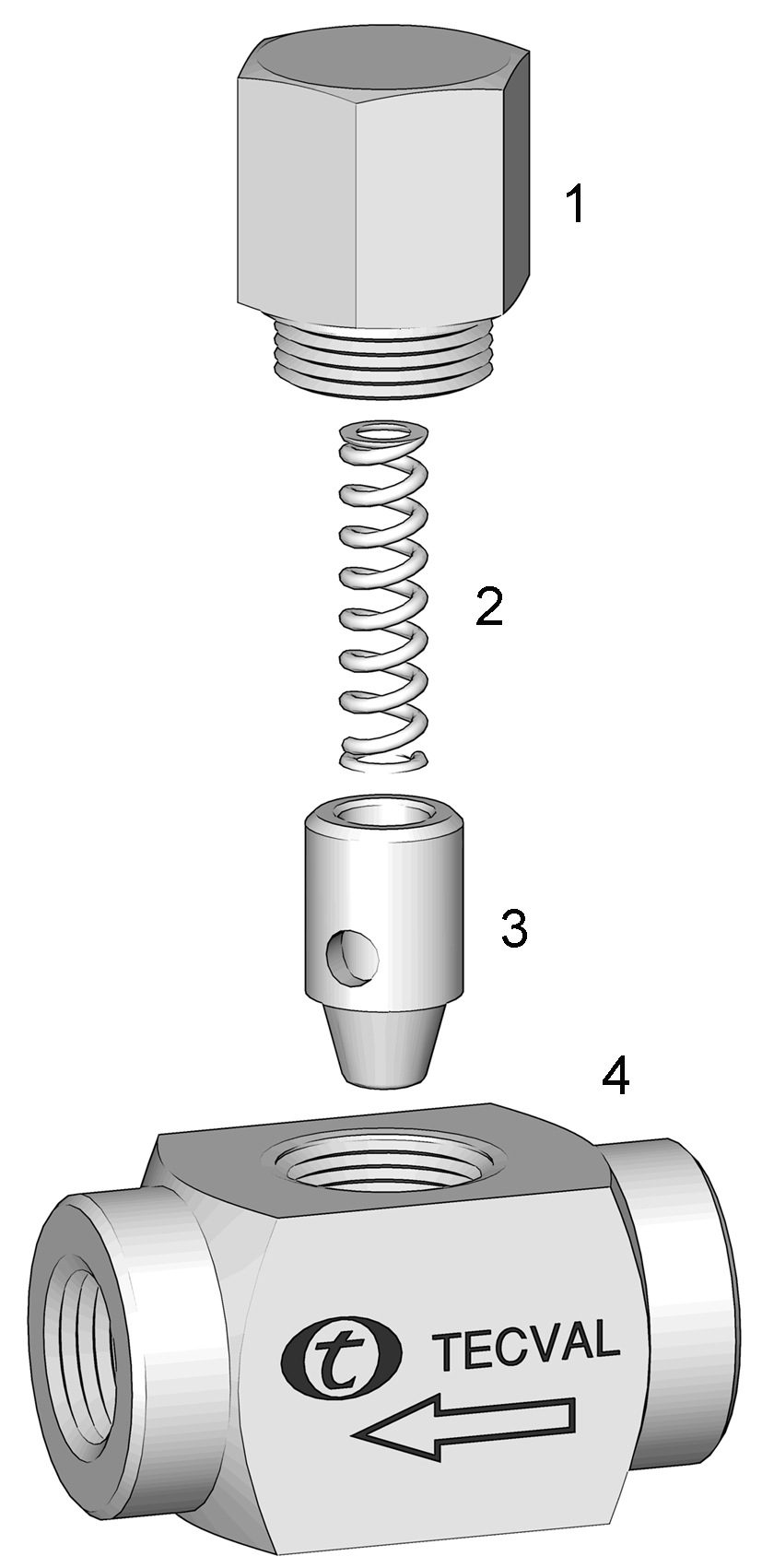

Tests 100% tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats. Upon request, the corresponding materials and test certificates can be delivered with the valve. Packaging All TECVAL valves are supplied packed in individual polyethilene airtight bags. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. Elastomers & Seats Seat (position 5) can be made of different materials: Nitrile B , FPM VI or Neopren N , considering the working conditions. Likewise the seats can be made in other materials upon request. |

|||||||||||||||||||||||||||||||||||||

|

Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

Materials

|

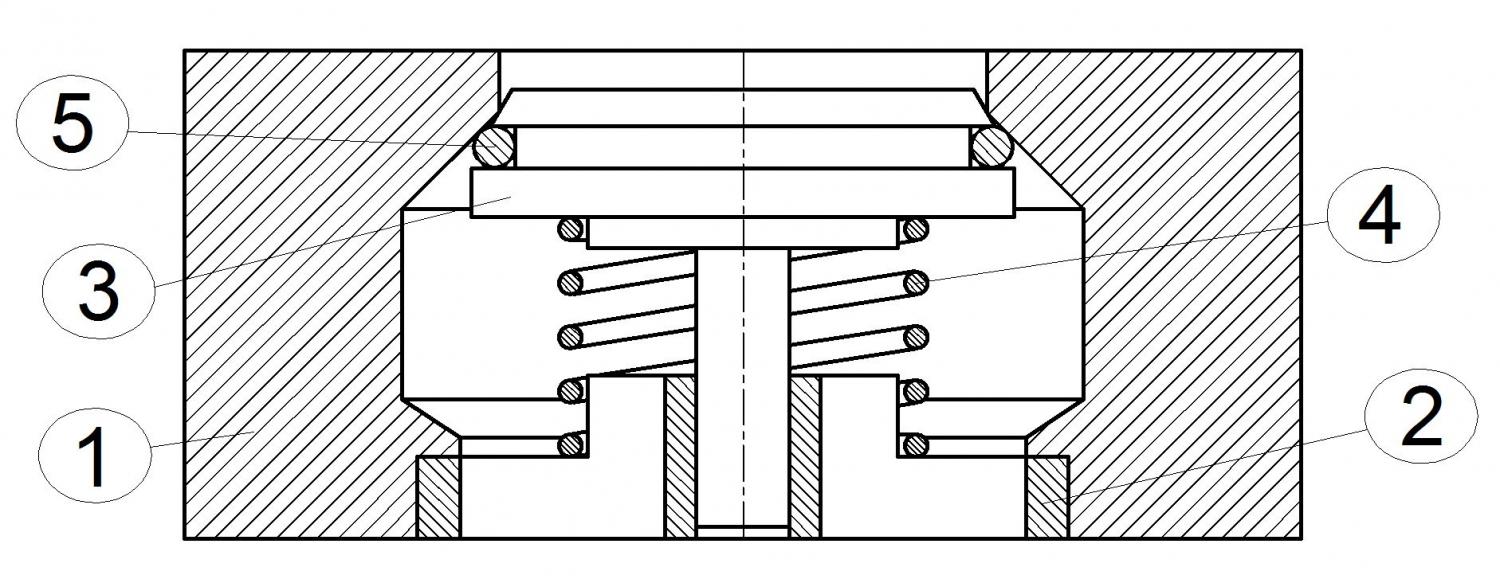

Tests 100% tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats. Upon request, the corresponding materials and test certificates can be delivered with the valve. Packaging All TECVAL valves are supplied packed in individual polyethilene airtight bags. End screw connections are protected with polyethilene caps. Everything is 100% recyclable. Elastomers & Seats Seat (position 5) can be made of different materials: Nitrile B , FPM VI or Neopren N , considering the working conditions. Likewise the seats can be made in other materials upon request. |

|||||||||||||||||||||||||||||||||||||

|

Features

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Options

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||