|

Materials

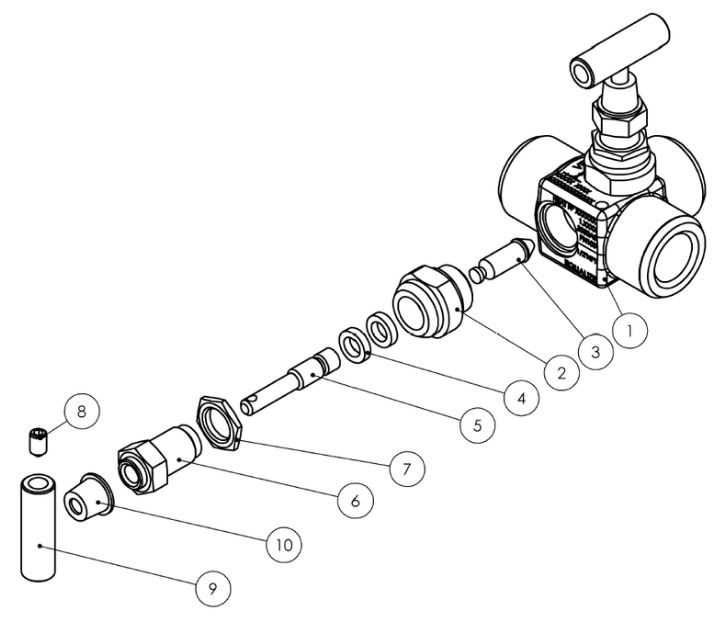

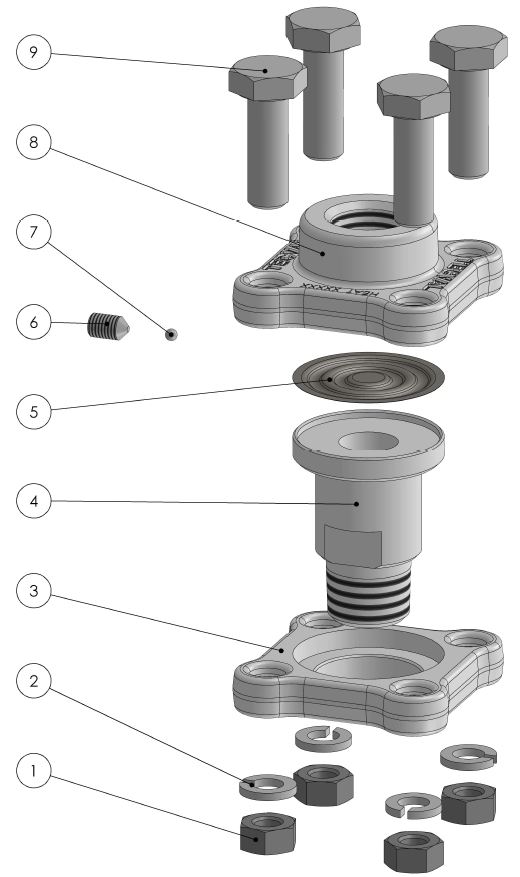

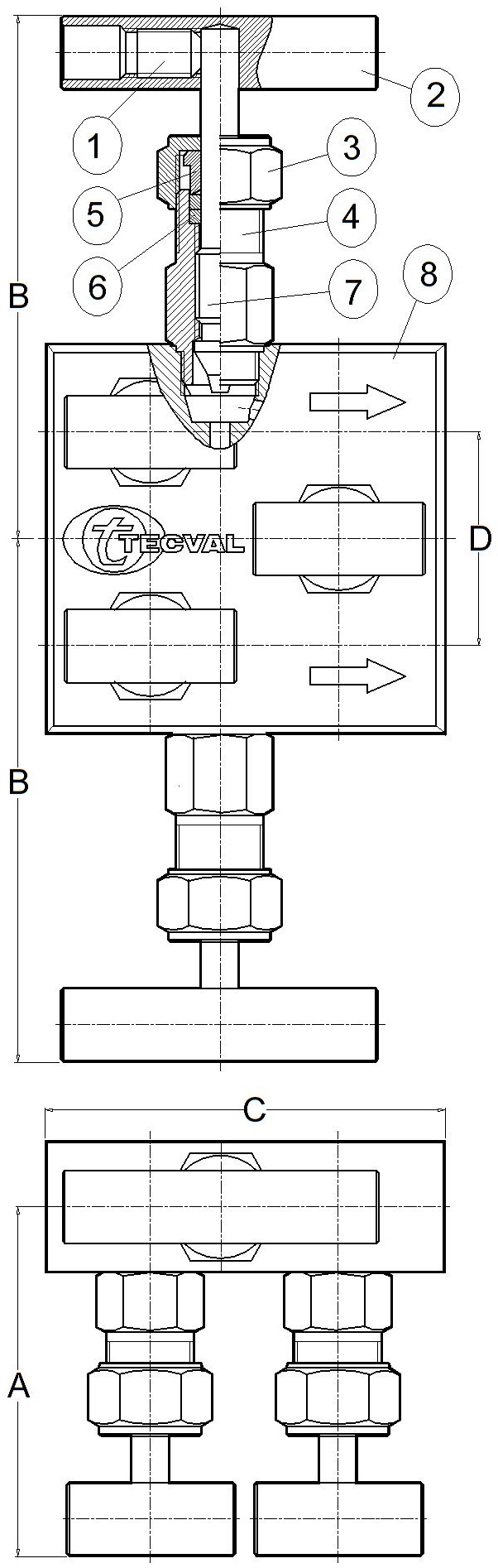

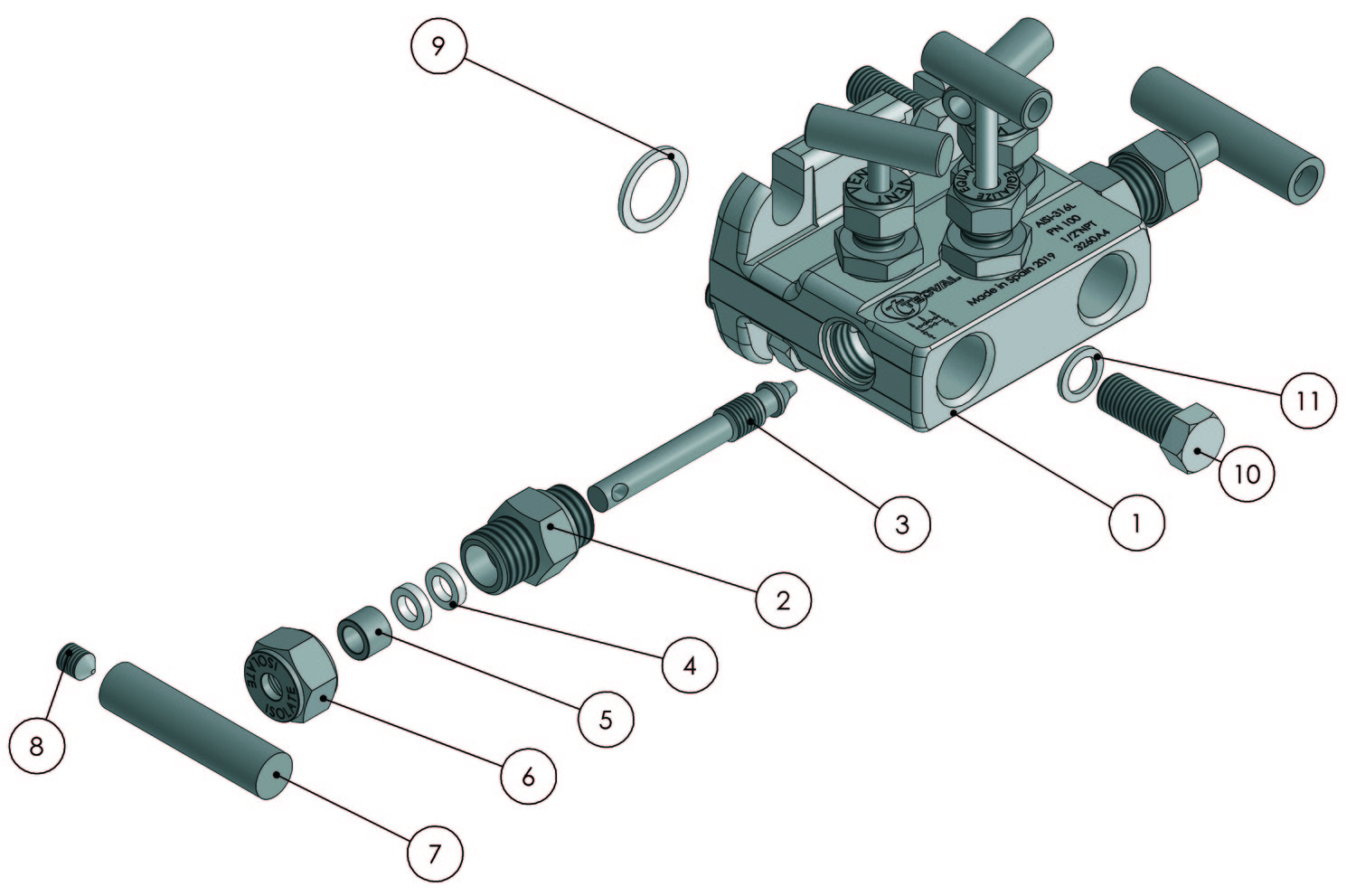

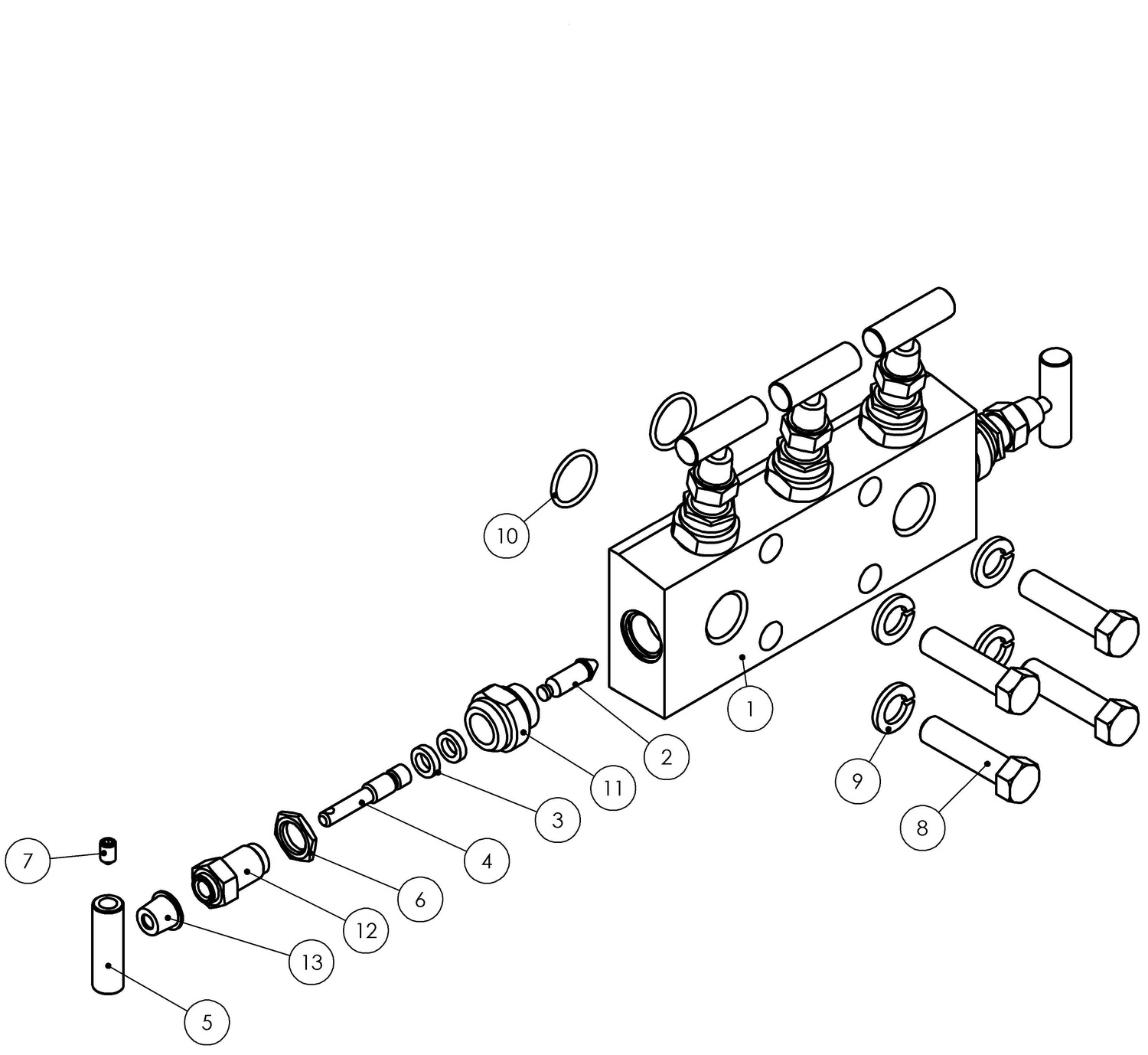

| Nº | Part | AISI-316L A4 | Duplex AD | SuperDuplex AS | Special alloys | | 1 |

Body | AISI-316L (1.4404) | Duplex (1.4462) | SuperDuplex (1.4410 / 1.4501) | Special alloy | | 2 |

Bonnet | AISI-316L (1.4404) | Duplex (1.4462) | SuperDuplex (1.4410 / 1.4501) | Special Alloy | | 3 |

Stem | AISI-316L (1.4404) | Duplex (1.4462) | SuperDuplex (1.4410 / 1.4501) | Special Alloy | | 4 |

Packing | P.T.F.E. | P.T.F.E. | P.T.F.E. | P.T.F.E. | | 5 |

Gland | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | | 6 |

Nut | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | | 7 |

Handle | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | | 8 |

Set screw | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | | 9 |

Joint | P.T.F.E. | P.T.F.E. | P.T.F.E. | P.T.F.E. | | 10 |

Screw | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | | 11 |

Washer | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) |

Special alloys

Among the wide range of alloys existing, TECVAL has selected those considered by our customers as most suitable, which we stock to ensure a quick and effective supply. Whether you do not find the required alloy or need further information about our exotic alloys valves and fittings, please address your inquiry to our Technical Department.

AISI-316Ti (1.4571) A6 , AISI-904L (1.4539) A9 , 254-SMO (1.4547) AV , Alloy 400 (2.4360) MO , Alloy 625 (2.4856) IN , Alloy 825 (2.4858) CO , Titanium Gr.2 (3.7034) TI , Hastelloy C-276 (2.4819) HA |

Ordering information

References are formed by three parts:

Valve Code -Look for it in the order codes chart on the previous page.

Option/s -If required, add the code/s from the options section on the previous page (in alphabetical order).

Material -Look for the code on the materials chart.

An example of manifold with one option:

Manifold MB-2.5DT 1/2"NPT AISI-316L movable stem tip:

3260 F A4 . The reference to place the order is 3260FA4.

|

|

|

Tests

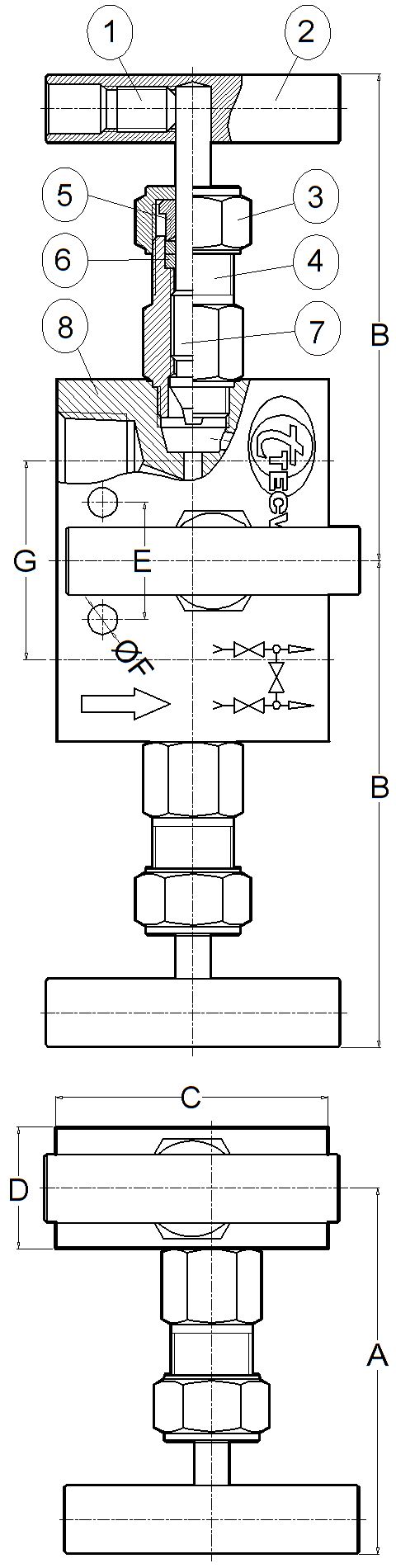

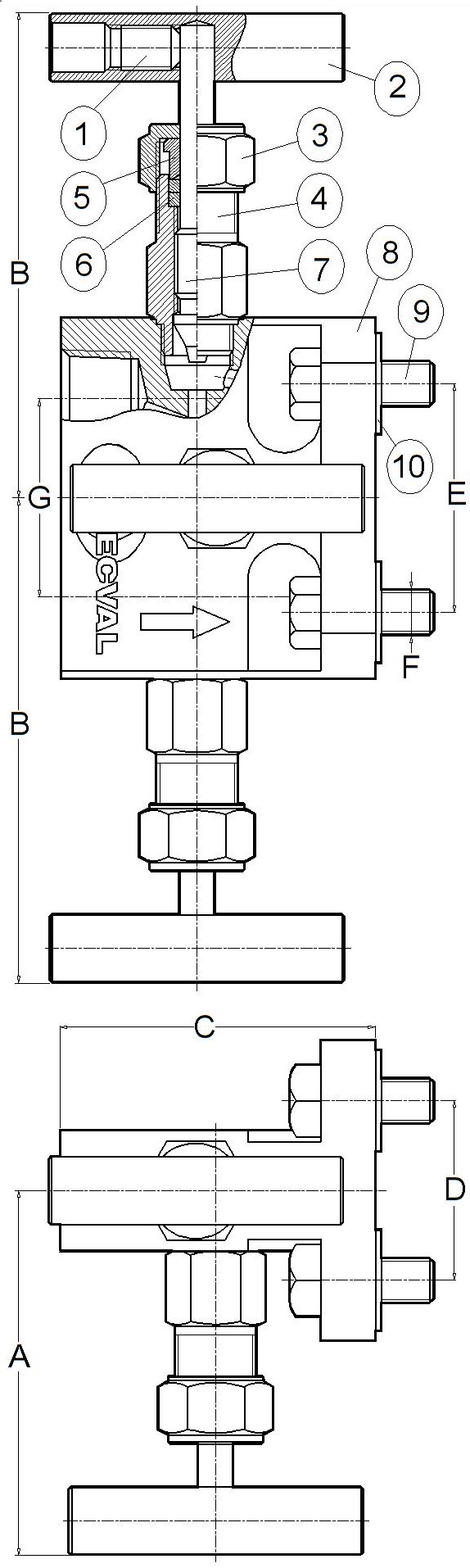

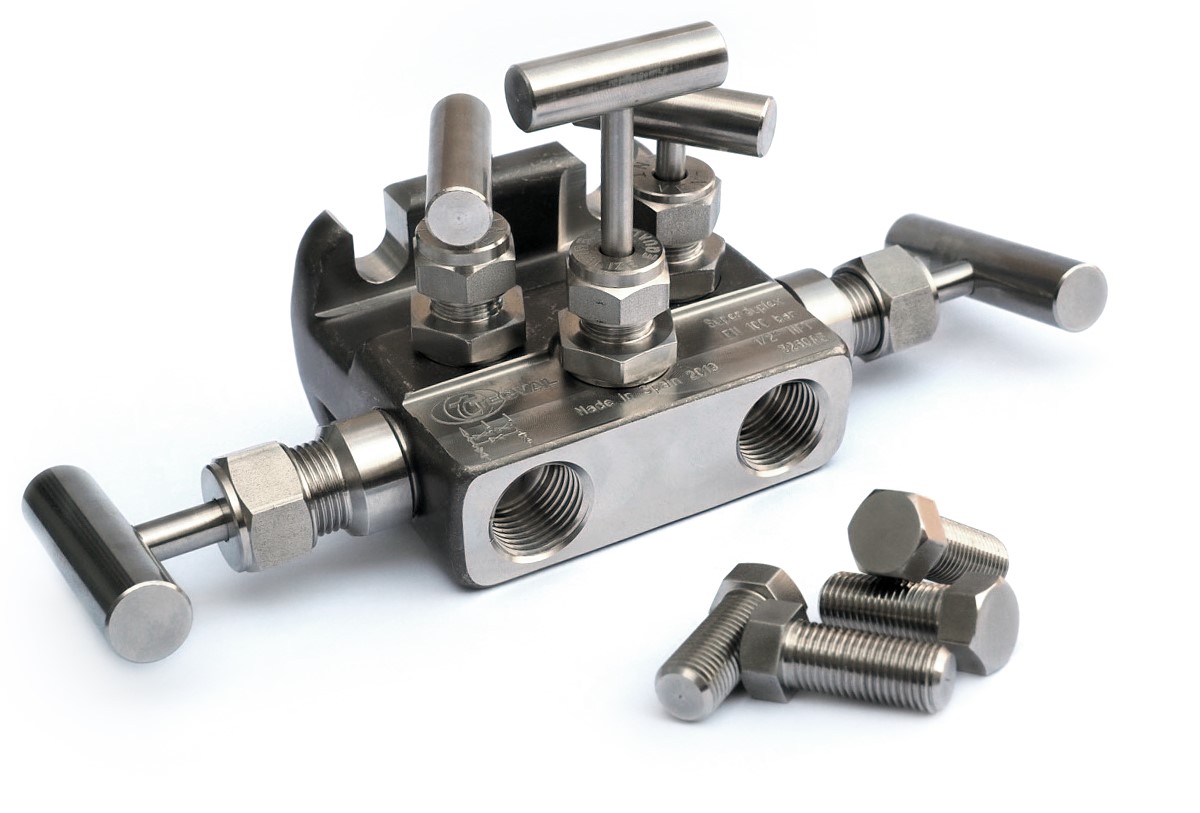

According to API STANDARD 598, each manifold is tested to check the leakage in the seat and packing. Under request, the corresponding materials and test certificates can be delivered with the manifold.

Packaging

All TECVAL manifolds are supplied packed in individual polyethilene airtight bags, which include the general features of the manifold. End screw connections are protected with polyethilene caps. Everything is 100% recyclable.

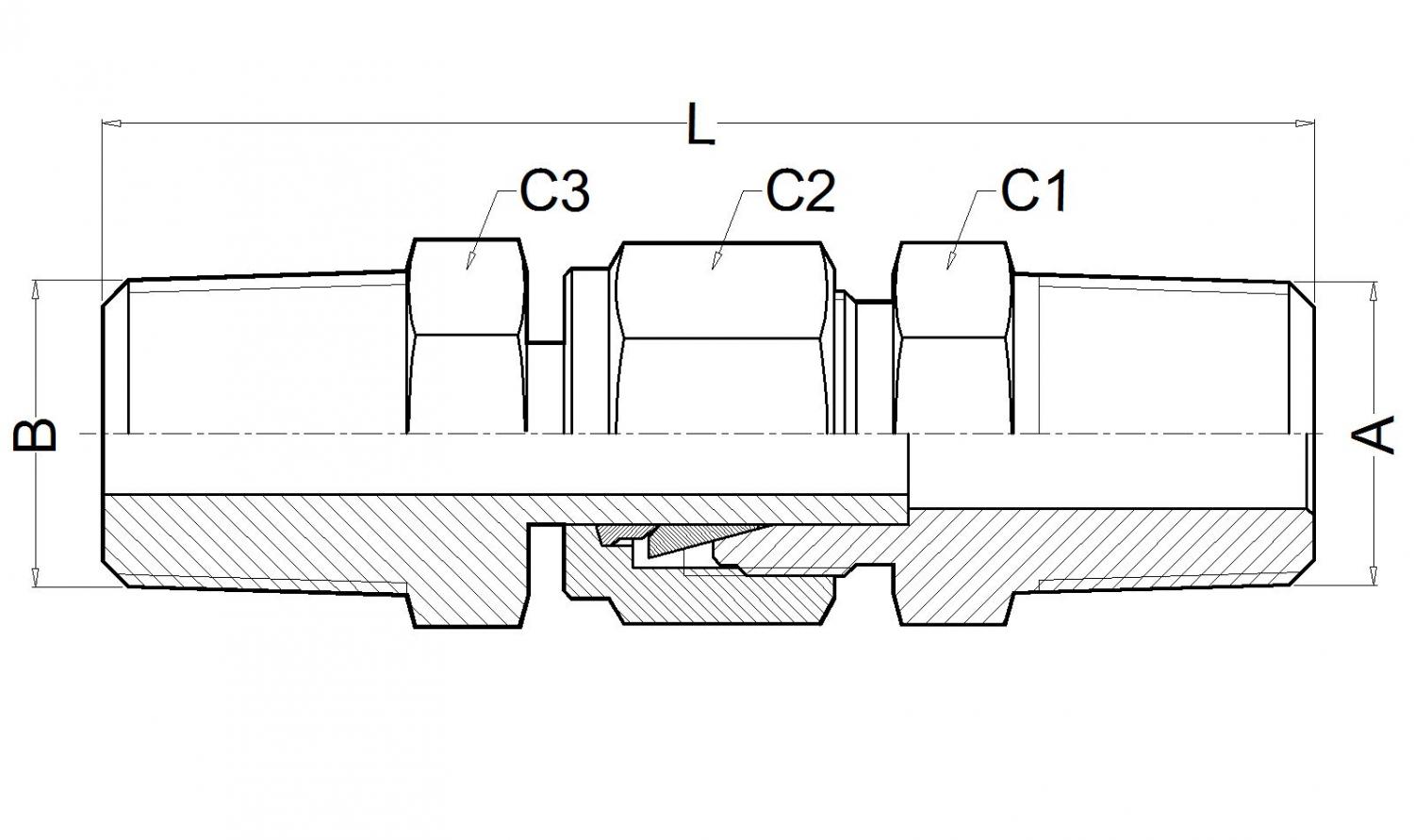

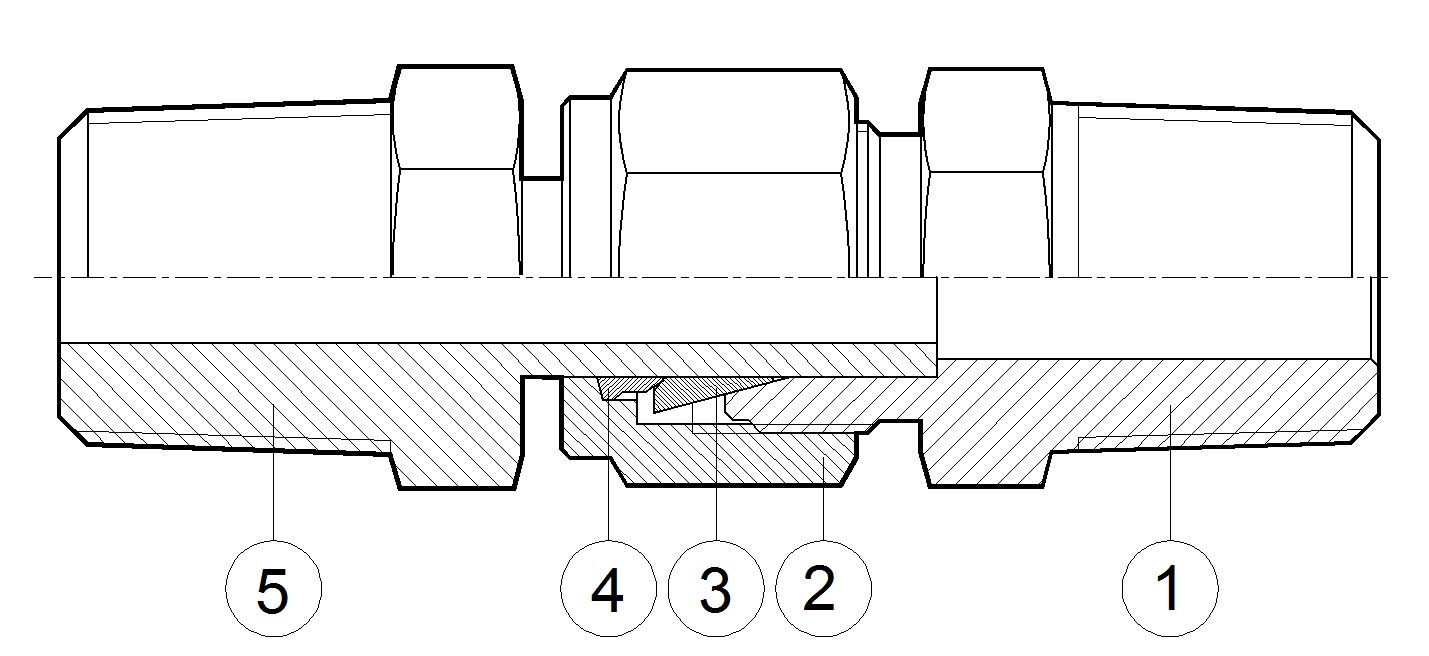

Maintenance Adjustment of the packings may be necessary during the working life of the manifold. The operation consists of turning the nuts (3) clockwise.

Manifolds with long no-working period may have a harder initial operating torque. |

Catalogue

Catalogue

Catalogue

Catalogue