|

Materials

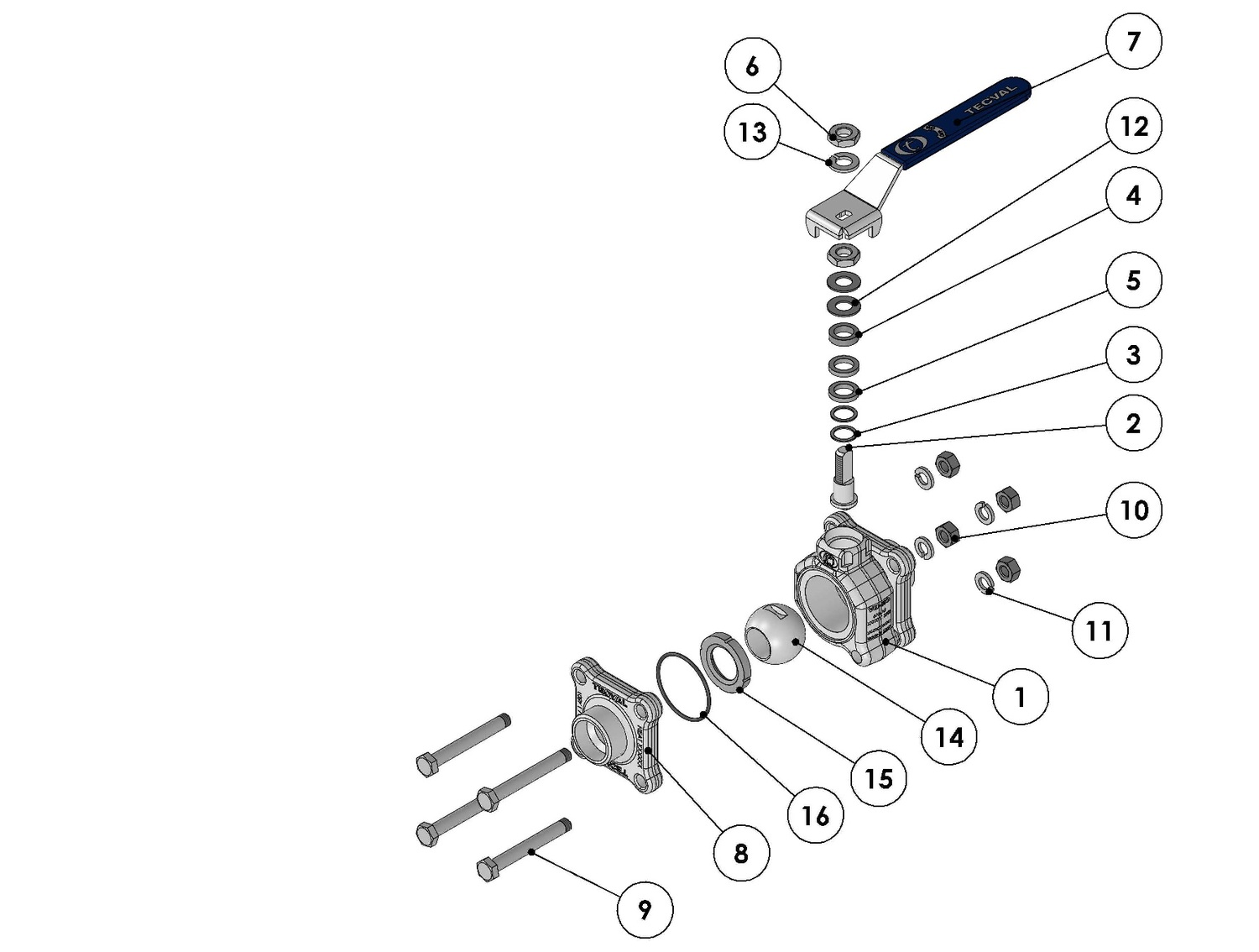

| Nº | Part | AISI-316L A4 | Duplex AD | SuperDuplex AS | Special alloys | | 1 |

Body | AISI-316L (1.4404) | Duplex (1.4462) | Superduplex (1.4410/ 1.4501) | Special alloy | | 2 |

Stem | AISI-316L (1.4404) | Superduplex (1.4410/ 1.4501) | Superduplex (1.4410/ 1.4501) | Special alloy | | 3 |

Stem bearing | PEEK | PEEK | PEEK | PEEK | | 4 |

Gland | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | | 5 |

Packing | P.T.F.E. | P.T.F.E. | P.T.F.E. | P.T.F.E. | | 6 |

Nut Handle | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | | 7 |

Handle | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | | 8 |

End connection | AISI-316L (1.4404) | Duplex (1.4462) | Superduplex (1.4410/ 1.4501) | Special alloy | | 9 |

Screw | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | | 10 |

Nut | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | | 11 |

Grower washer | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | | 12 |

Spring washer | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | AISI-316L (1.4404) | | 13 |

Handle Grower | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | AISI-316 (1.4401) | | 14 |

Ball | AISI-316L (1.4404) | Duplex (1.4462) | Superduplex (1.4410/ 1.4501) | Special alloy | | 15 |

Seat | TFM | TFM | TFM | TFM | | 16 |

O-ring | EPDM | EPDM | EPDM | EPDM |

Special alloys

We can manufacture in:

AISI-316Ti (1.4571) A6 , AISI-904L (1.4539) A9 , 254-SMO (1.4547) AV , Alloy 400 (2.4360) MO , Alloy 625 (2.4856) IN , Alloy 825 (2.4858) CO , Titanium Gr.2 (3.7034) TI , Hastelloy C-276 (2.4819) HA

Please address your inquiry to our Technical Department.

Pressure/Temperature Service Ratings

Pressure Ratings in bar for standard combinations bodies and seats.

|

T(ºC)

|

AISI-316L+TFM |

AISI316L+PEEK |

Superduplex+TFM

Duplex+TFM

|

Superduplex+PEEK

Duplex+PEEK

|

| -20 |

135,0 |

206,8 |

135,0 |

228,6 |

| 0 |

135,0 |

206,8 |

135,0 |

228,6 |

| 50 |

135,0 |

200,1 |

135,0 |

228,6 |

| 100 |

97,6 |

173,9 |

97,6 |

223,3 |

| 150 |

62,8 |

157,0 |

61,6 |

209,4 |

| 200 |

22,8 |

145,8 |

22,8 |

198,2 |

|

Ordering information References are formed by three parts:

Valve Code Look for it in the order codes chart on the previous page.

Option/s If required, add the code/s from the options section on the previous page (in alphabetical order).

Material Look for the code on the materials chart.

Example of ball valve VB-20 with two options:

Ball valve VB-20 1"NPT (SB) Superduplex with handle safety lockout and FPM seals:

6102 VI W AS The reference required to place the order is 6102VIWAS .

|

|

|

Actuators Upon request, ball valves VB-20 can be delivered with:

- Pneumatic actuators: either double acting (DA) or spring return (SR).

- Electrical actuators: of 24V, 115V and 230V can also be assembled.

For detailed information please consult the sections on Electric and Pneumatic Actuators.

Tests

100% valves are tested in accordance to API STANDARD 598, each valve is tested to check the leakage in the seats and packing. However they can also be tested under other standards such as EN12266. Upon request, the corresponding materials (EN10204 3.1) and test certificates can be delivered with the valve.

Maintenance Valves with long no-working period may have a harder initial operating torque. Are designed to be operated in a fully open or fully closed position. |